Okay, so I was playing with the configurator and then copied the stuff over from there and added what you were saying, so… hoping this is right, I have:

#ifdef CONFIG_TOP

#include "proffieboard_v3_config.h"

#define NUM_BLADES 1

#define NUM_BUTTONS 2

#define VOLUME 1000

const unsigned int maxLedsPerStrip = 144;

#define CLASH_THRESHOLD_G 1.0

#define ENABLE_AUDIO

#define ENABLE_MOTION

#define ENABLE_WS2811

#define ENABLE_SD

#endif

#ifdef CONFIG_STYLES

class BlackPower {

public:

LayerRunResult run(BladeBase* base) {

return LayerRunResult::UNKNOWN;

}

SimpleColor getColor(int led) {

return SimpleColor(Color16(0,0,0));

}

};

#endif

#ifdef CONFIG_PRESETS

Preset presets[] = {

{ "Charging",

ChargingStylePtr<BlackPower>()},

{ "TeensySF", "tracks/venus.wav",

StyleNormalPtr<CYAN, WHITE, 300, 800>(), "cyan"},

{ "SmthJedi", "tracks/mars.wav",

StylePtr<InOutSparkTip<EASYBLADE(BLUE, WHITE), 300, 800> >(), "blue"},

{ "SmthGrey", "tracks/mercury.wav",

StyleNormalPtr<RED, WHITE, 300, 800>(), "red"},

{ "SmthFuzz", "tracks/uranus.wav",

StylePtr<InOutHelper<EASYBLADE(OnSpark<GREEN>, WHITE), 300, 800> >(), "green"},

{ "RgueCmdr", "tracks/venus.wav",

StyleNormalPtr<WHITE, RED, 300, 800, RED>(), "white"},

{ "TthCrstl", "tracks/mars.wav",

StyleNormalPtr<AudioFlicker<YELLOW, WHITE>, BLUE, 300, 800>(), "yellow"},

{ "TeensySF", "tracks/mercury.wav",

StylePtr<InOutSparkTip<EASYBLADE(MAGENTA, WHITE), 300, 800> >(), "magenta"},

{ "SmthJedi", "tracks/uranus.wav",

StyleStrobePtr<WHITE, Rainbow, 15, 300, 800>(), "strobe"}

};

BladeConfig blades[] = {

{ 0, , CONFIGARRAY(presets) },

};

#endif

#ifdef CONFIG_BUTTONS

Button PowerButton(BUTTON_POWER, powerButtonPin, "pow");

Button AuxButton(BUTTON_AUX, auxPin, "aux");

#endif

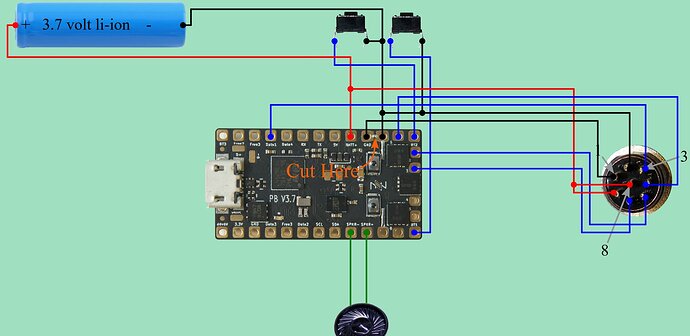

And Profezzorn, I did selected blade plug in the options which is when it gave me the cut trace on the board. Screenshot attached:

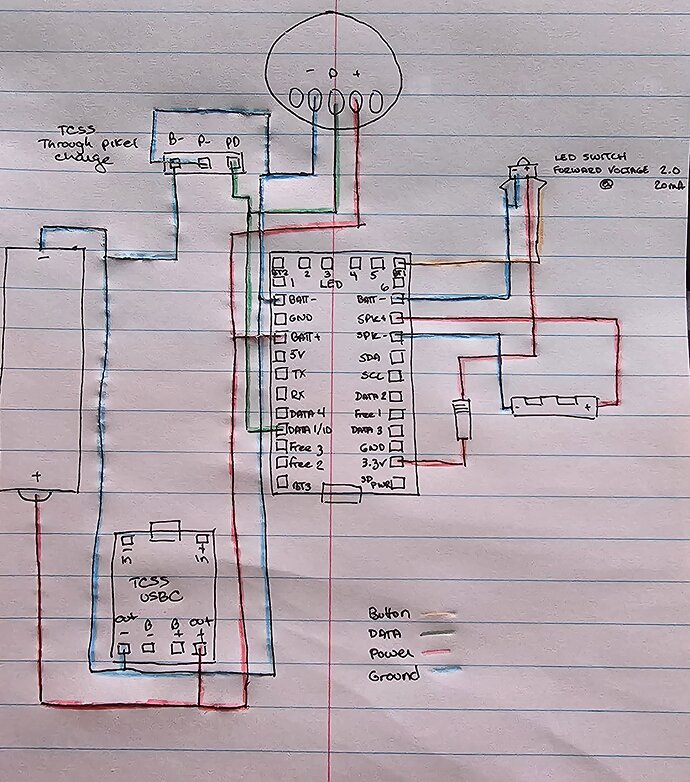

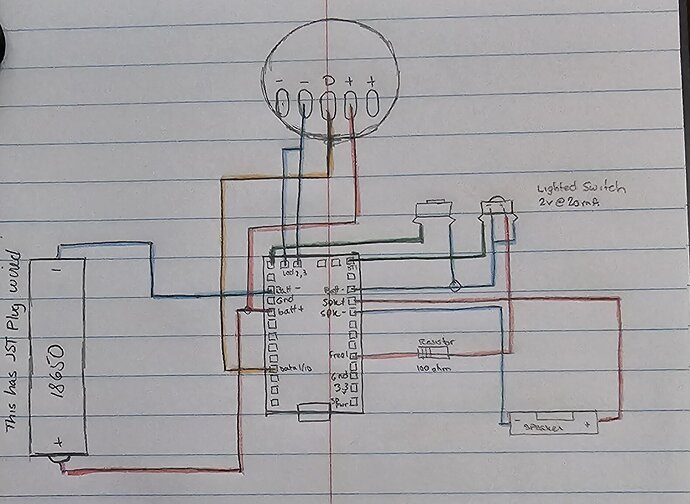

I just adapted my wiring to the one that TCSS sells that I was planning to get obviously, unless that is incorrect for the configurator for this setup?

Edit: I think I read your thing wrong as far as where to put the charging code… I’m assuming it needs to be moved down to the BladeConfig section and be { 0, , ChargingStlePtr<BlackPower>() } instead of where I have it?

Also, being you said 65ohm for the switch LED, would it still be 65ohm 1/8w or would that requirement change as well?