Hello,

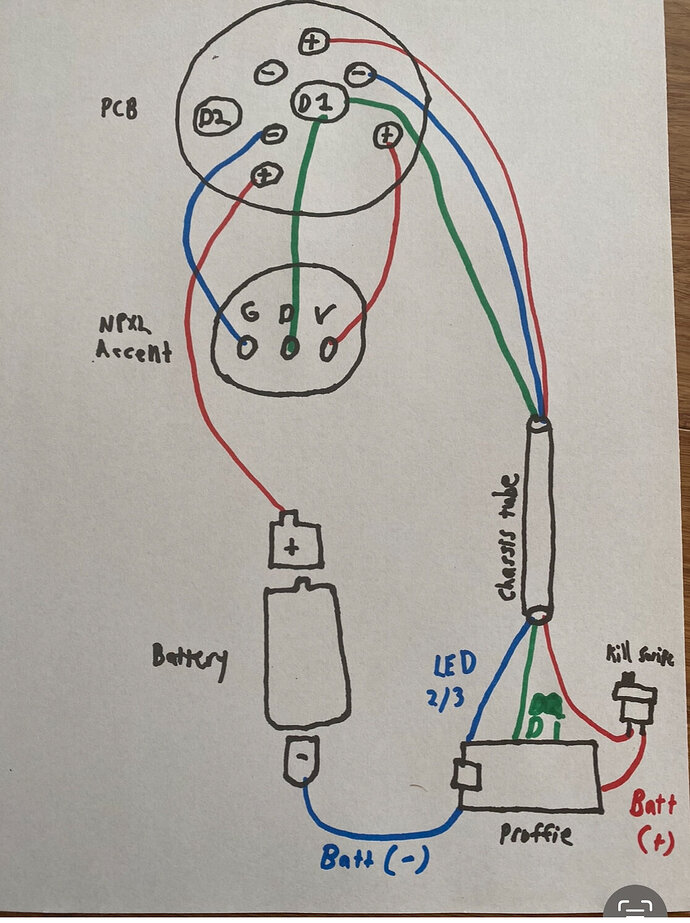

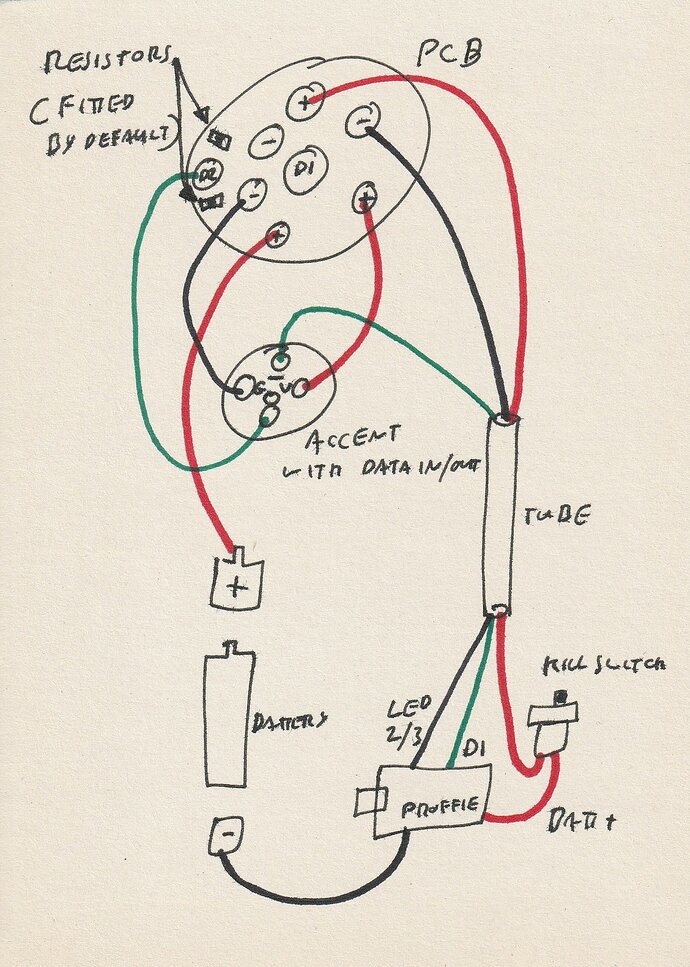

Wanted to see if I could get assistance on how to wire up Goth3D Metal Master Chassis with Proffieboard, including neopixel accent connecting to the bottom of the PCB.

For my configuration, I want to have the accent LED (crystal) behave differently from the main blade. I have it set as ‘blade 2’ with 1 LED. Do I need two data lines for that? One for main blade and one for accent? Or do I only need one data line with the accent wired between the PCB and the board?

My understanding is the two data line options on the PCB are only if you want the PCB to have an independent setup from the main blade, which I’m not interested in (good with version 2). But does the accent need its own unique data line to the board?

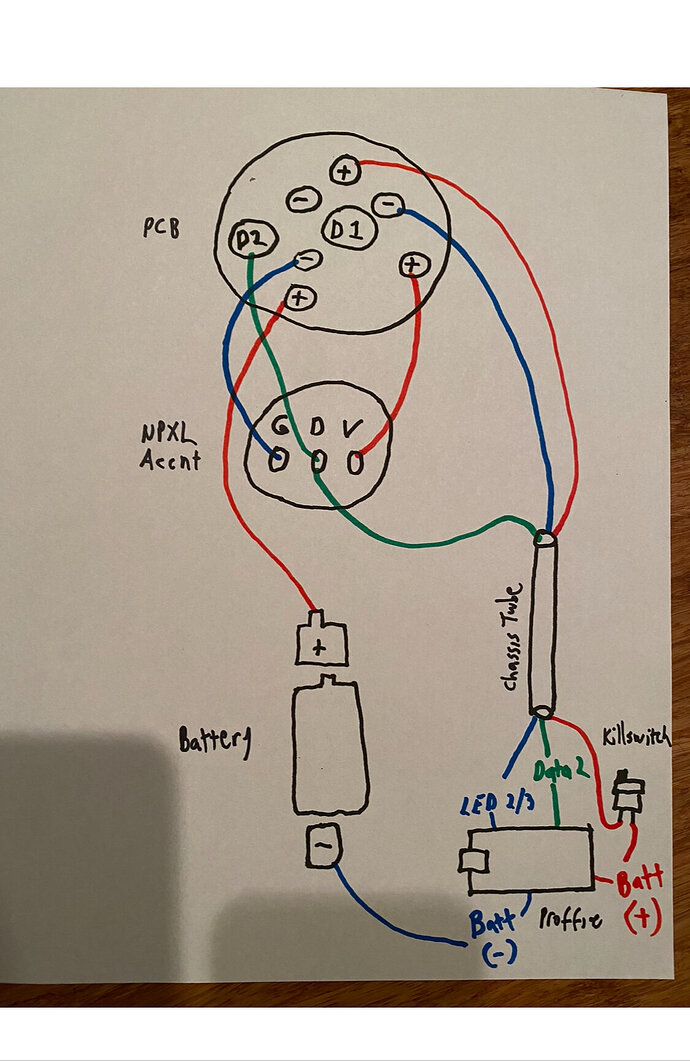

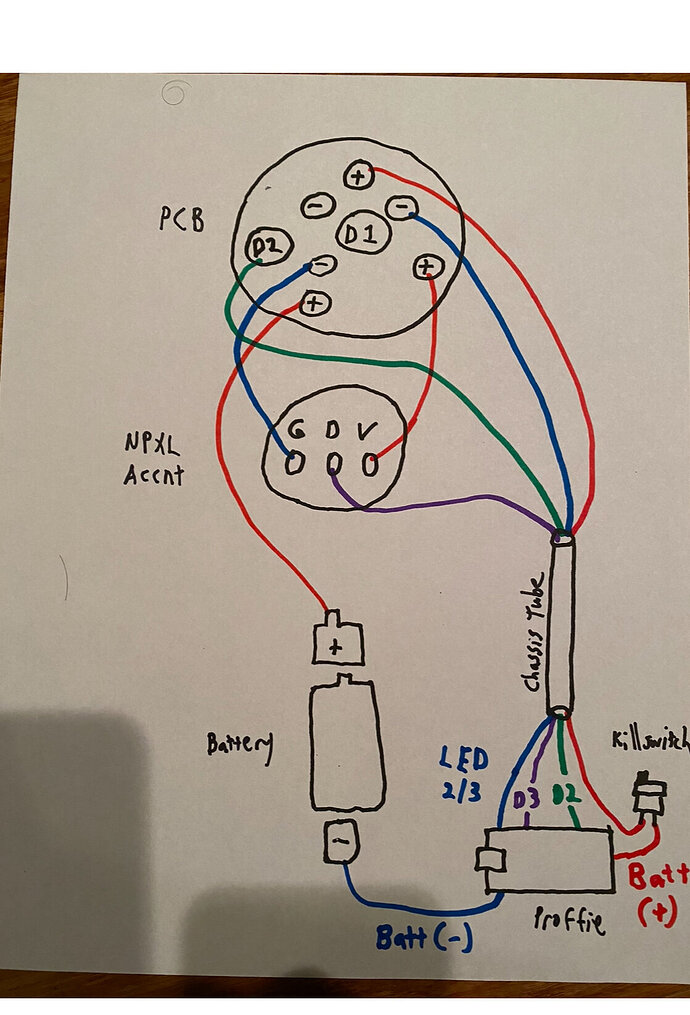

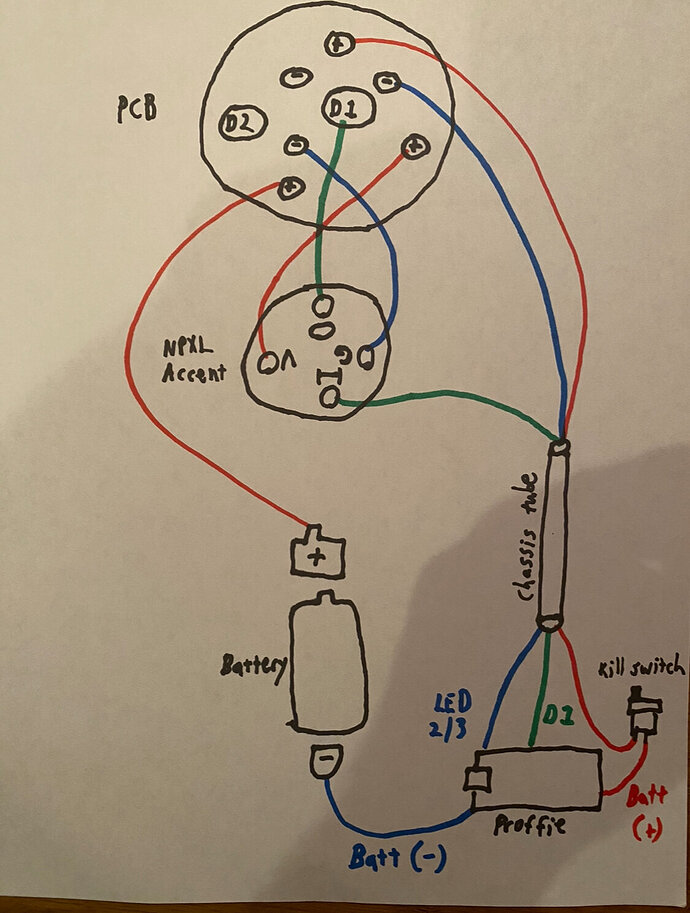

I have two different wiring scenarios below to illustrate, if anyone can look at my overall wiring setup and advise if one or neither would be correct.

FYI The chassis is designed for the wires to go through a narrow tube, to travel through the hilt and connect to the back portion of the chassis, where the board is located.

One data line:

Two data lines; one straight from accent to board:

Thanks