It’s been some time since I made a prop for my wife, and she’s not interested in anything that’s not fully themed to one of her lewks. Steampunk is on the list (also Star Trek, vamp, sith vibes) and there are only a few steampunk items that don’t lead to the full-on HG Wells Time Machine Back Pack trap ![]()

So what to build?

First, hat and goggles. Check. Adafruit basically made sure everyone that wanted the basics could do a really good job with a little time. The NY RenFair also has good costumes. Check.

What form factors remain? Eureka! It’s gonna be a cane! “And what are your requirements, my love?” I asked. Many times just to be sure. Here’s some of them

1 - Light weight

2 - Somewhat dim…it’s not cute to bring a giant laser stick to an office event or private party but

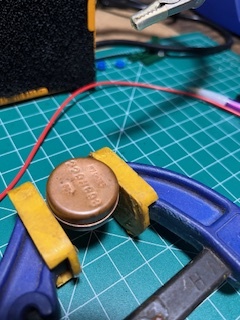

3 - Replacable battery for the NYC Halloween parade (anxiety already building…it’s been years)

3 - Fireflies effect to match the hat

4 - A cool, spooky voice for settings

5 - Cheap - ruled out a lot of obvious steampunky bits

6 - Made from as much “real” junk as possible

7 - Stuff happens when you twist or tap it, but not too much stuff

8 - Controls have to be “super simple”

9 - Sound (hum) should be subtle

10 - It should do one thing really well (not a lot of presets needed)

11- Gotta be skinny

12 - No bright, migraine inducing flashes

And my own rule: it has to be cool enough that I get to enjoy hearing her say “oh, thanks. my husband made it.”

It starts with some parts. Then pics. Wrap it up with a demo vid. And of course I’m excited to share the final results of the help I’ve received already on this fantastic forum.

I’ll begin to list parts here, and carry on the next time I take a laptop siesta.

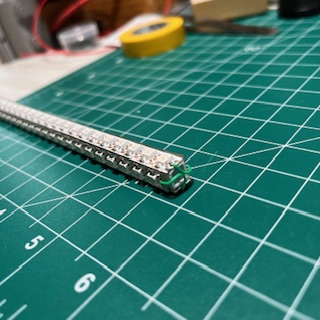

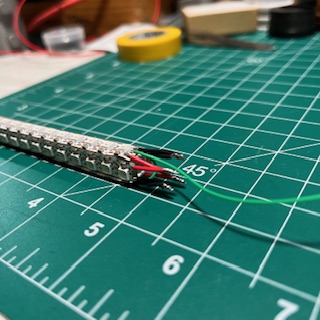

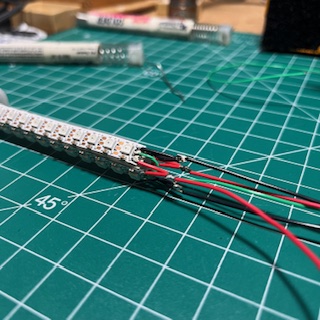

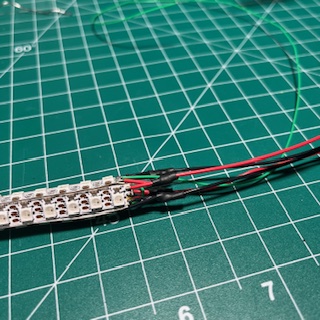

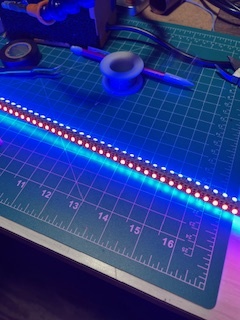

The blade is a quad blade zig zag. I dont need the tip to illumiate, so i used some of these as the core:

They’re super light weight and connected with a thin wrap of:

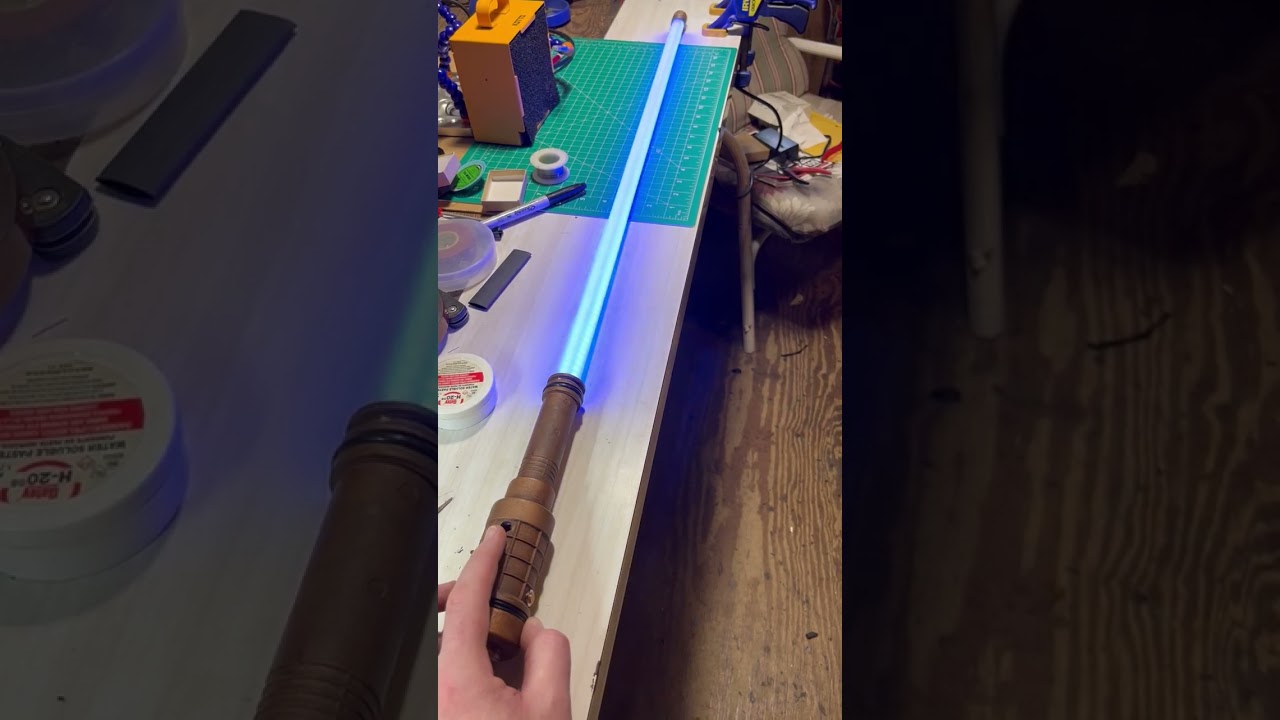

The casing is from TCSS - 3/4":

TCSS 3/4 Trans White Blade Tube

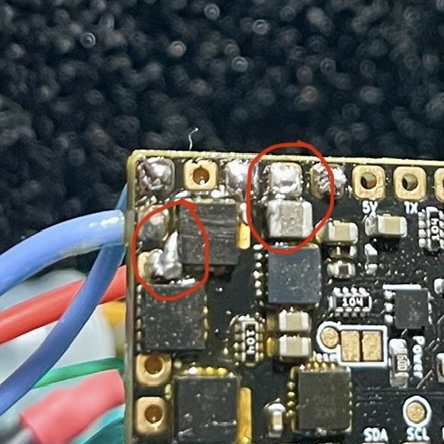

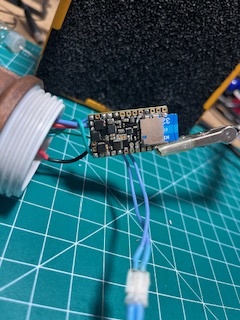

And the LEDs and Proffie come from Elecronics123. It’s all about the skinnyz:

Pics soon…it’s almost ready to test and I’m still working on proper diffusion in such a narrow blade.

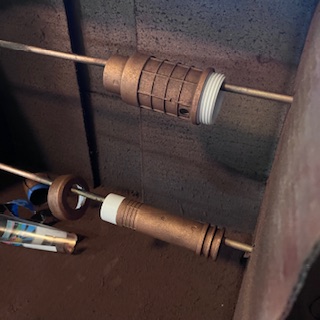

But the handle, the hilt I suppose, took some thinking. I stared at walls of plumbling parts. Real metal was too heavy. I live on a semi industrial block and asked local guys if I could check out their parts bins. Finally I found this:

The battery can sit in the expander, which can be pulled out and inverted. The PVC is light and strong, and it looks like a lantern. It’ll need paint but steampunk painting is time consuming (dry brushing, etc) but not too hard. The top is threaded and removable.

More parts started making sense, but I’ll take a break there. Thanks for looking!