Well, technically I am doing 60-degrees per 4-inches, which is 101.6 mm…but basically, yes.

My printer was able to handle the overhangs created by the model without any supports…I think it worked because the whole wall is not that steep, just the ends.

Edit: I would definitely recommend trying to print the helical cores on their side, since I wasn’t able to break the one I printed when bending it.

1 Like

i will certainly have a go.

i’m also checking out a helical spline add in for fusion to get a better helical twist.

1 Like

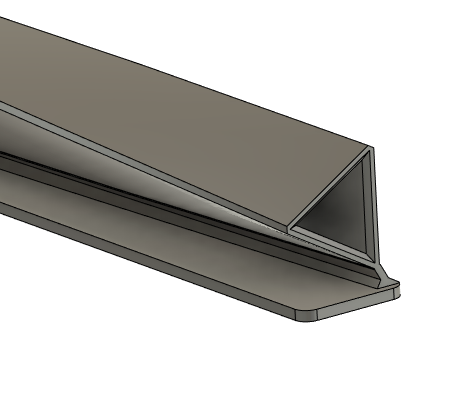

I changed the design slightly for the final print. Now there is just a 0.125" hole through the center so that I can just use small sections of aluminum tube to connect them, rather than helical plugs…yuck.

1 Like

looks spot on.

love the idea of using a rod to line them up on.

1 Like

You can buy a IP65 Waterproof in Silicon Coating ws2812,It same look like you do.

1 Like

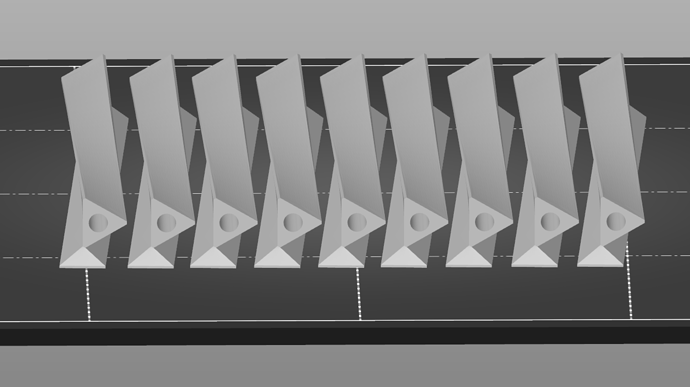

I printed a test piece out after I changed the extruded profile so it now coils correctly.

The twist is a bit aggressive and the strips definitely don’t form to it. But proves the difference between the how we were doing it and what we do now.

1 Like

Very nice!! It is cool looking, that’s for sure! Definitely more twist than I think the strips can handle though.

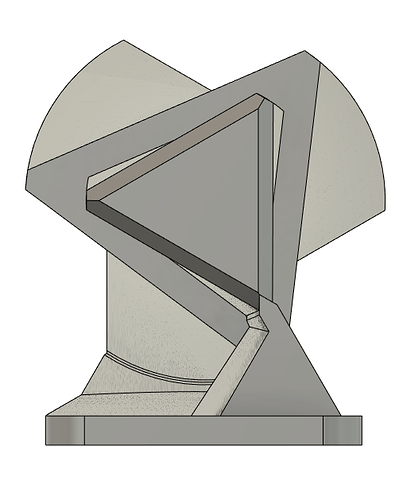

I spent some time this morning and came up with a solid printable model. The connection stub is actually modeled into the core now, and I decreased the angle to 53-degrees per 100 mm in order to keep overhangs from getting too steep for the printer when adding the 12.5mm stub.

The whole core is printed connected to a platform that can be snapped off. There are small grooves where the platform connects to the core, and the platform is split between the core and connection stub to facilitate easy removal:

Finally, the core is mostly hollow, with some tolerance for the stub to insert:

I’ll be able to set up the print the afternoon after work and hopefully do some assembly as well.

2 Likes

Fantastic work there.

Look forward to seeing the results

I guess when we have advanced bladestyle tech, its time to experiment with the hardware! Great job!

1 Like

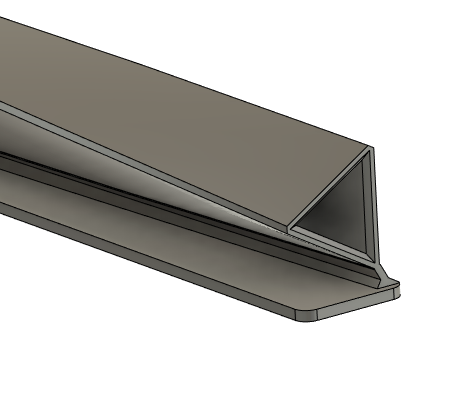

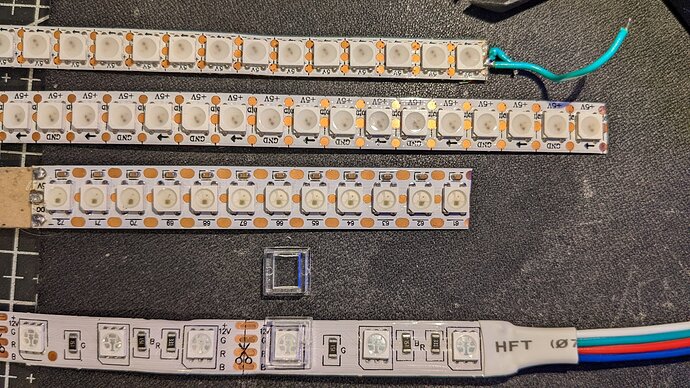

Well, following up on this, I received these and they’re way too big for the APA105 strips I like to use.

Anybody want 600 lenses?

They’re these:

1 Like

I’m assuming they would fit the more common 2811 / 2912 / 2813 strips?

if so i would be willing to have 300 to test on my next blade build.

1 Like

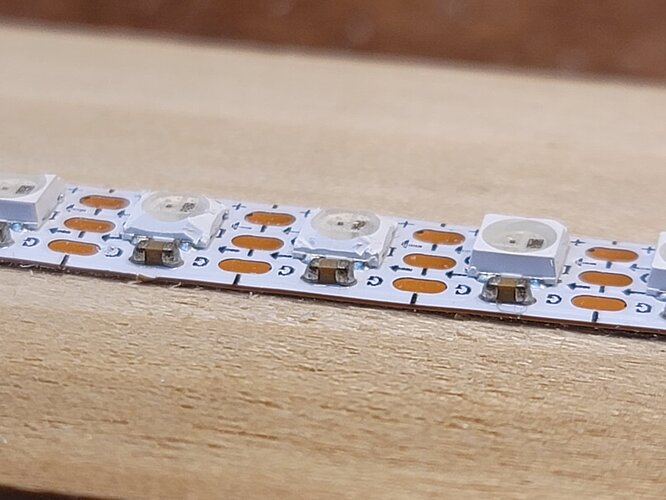

Actual measurements at the base are 9.1 x 9.3 and 3.9 high.

Due to the density of these strips (all 2mm between pixels), doesn’t matter which width strip, and they are probably meant for low density strips as shown.

thats a shame.

i wonder if they would fit it the sides were sanded down?

clutching at straws i know but it was just a thought.

For that effort, probably better/might-as-well just sand down the pixels ?

2 Likes

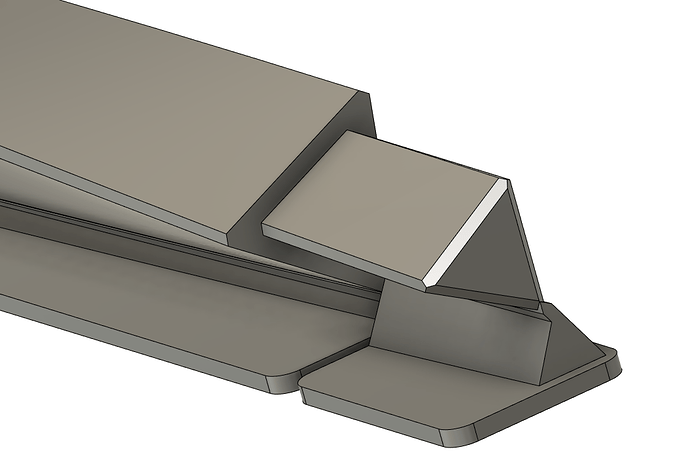

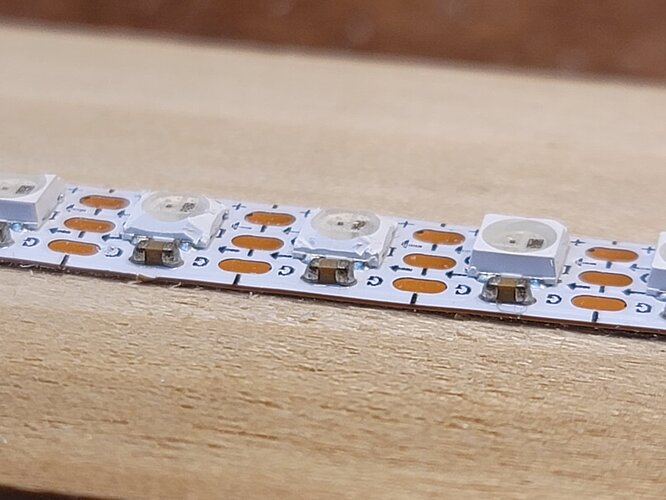

I finished that blade …390 pixels. It wasn’t too bad, maybe 2 solid hours of work. I worry I probably shortened the life of at least a few of the pixels. Thankfully they all still work:

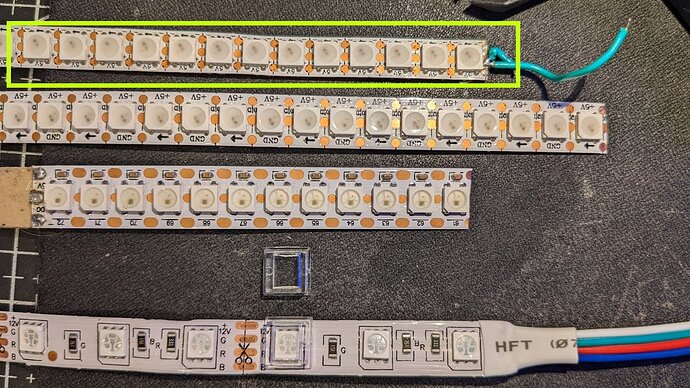

May I ask what the strip is at the top of your photo:

Newstar 8mm APA105 strips.

Etsy shop I get them from has nothing at the moment:

Maybe here, no idea if this is a trustworthy vendor:

Conversation about them in the saber community back in the day:

https://tinyurl.com/y36atq7l

Personally, I like them, although a pair of them leave more room for side-to-side wiggle in the finished blade.

My standard method is to cellophane wrap them for diffusion/thickening, then insert in foam.

I picked up a roll of clear shrinkwrap and might try that next time around.

The brightness issue argued by Dmitry is nothing I’ve noticed.

1 Like

Great thank you! I may have to pick up a couple strips to try them.

I use clear shrinkwrap in mine and it does a decent job. Only concern is heat.

1 Like

What a fun thread to look through. Any updates from anyone?

2 Likes

Sort of…@Driftrotor and I received some samples from a Chinese company that manufactures specialty optical films. We’re just starting testing, but I can say some of the effects are pretty wild.

Hopefully we will have a solid update a few weeks from now.

2 Likes