Agreed, so just go for the helicoil tri core and see what that brings.

The print times are much longer though.

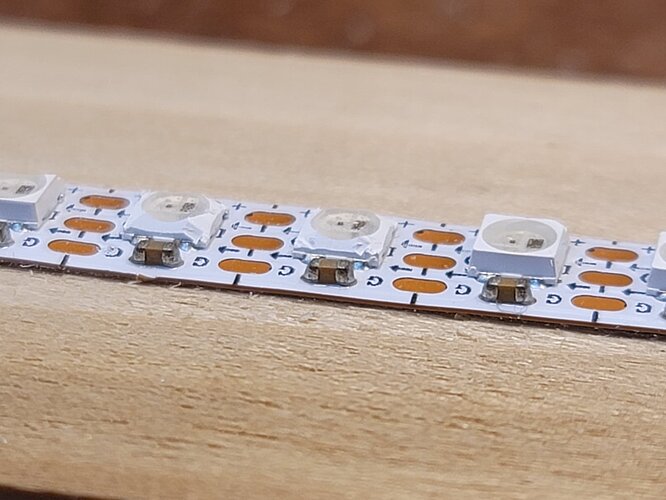

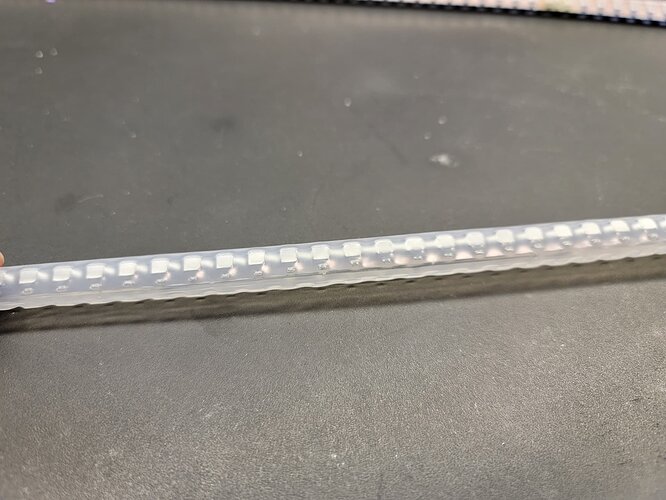

I have a set of cheep pixel strips that I could mess with to see if the lens idea would work.

So, all of this is obviously far above my head, but what is the end goal? A much brighter pixel-based saber blade? A more stable pixel blade? I know I use my pixel-based sabers in choreographed light saber battles as part of Saber Guild. So, I am always curious about new blade designs and what the end result of the new design would be. For instance, I have heard that the KR strips were REALLY bright, but the rigid lattice made them not so good for saber dueling? Maybe I am remembering wrong.

In any case, I am just really curious what the end result / goal is. Always looking for a better blade.

Side question, when using three strips like that, would you need to step up to a larger battery like a 21xxx size battery? Also, why is it that CFX requires a 15AMP Max battery but Proffie is ok with a 10AMP battery? All of my 18650’s for my sabers are 15AMP, but I have seen 10AMP batteries that have a higher capacity, like the ones I use for my flashlights.

The end goal is, in general, to have a brighter blade…but also one that has a nice even light. Shadows, lines, or bright spots take away from the realism. These problems get worse the more leds you try to shove in the blade.

I also like to duel with my sabers, so making the pixel blades more durable is always in the back of my mind as well.

As for your battery question, it really depends on how many leds you are trying to power. The board and speaker only use between 250mA and 750mA, so all the current is going to the blade. A regular two-strip blade uses between 3 to 6 amps, depending on what color it is displaying. The tri-strip blades are obviously going to be more like 5 - 7.5 amps.

If your batter can sustain the blade current without shutting off, you should be fine…e.g. you don’t need 15A to run CFX or proffie. I always use 21700 batteries if I have room, because they last longer, but if you’re okay with lower runtime, 18650 works fine too.

Many thanks for the reply. I was just really curious about this. I am always looking at what is the best of breed in sabers these days. Have you investigated the strips from KR Sabers? I know there was a lot of interest in what he was doing, and I had not heard much about it recently. But then I dropped Facebook over a year ago now.

I am going to watch this one because I am really curious to see what you come up with.

Yes, I have built blades with both his V1 and V2 strips. They are very easy to install, but because they have a thick PCB, the shadowing is pretty bad. I wouldn’t say they are much brighter than a normal two-strip blade, nor are they approved for dueling.

I’m not saying they’re bad, just not the perfect solution.

The KR sticks are two-sided so can’t be used for these projects.

Ahh, many thanks for the explanation. I am most appreciative of it.

Looks like you’ve been busy.

I’m having a day off as it my b-day.

But I did think of something interesting.

As this thread has evolved somewhat and now seems to be blade building ideas in general… cough. Sorry I may have helped on that.

My idea is this.

We now have the technology to make bendable tv screens.

What if we could specify a screen size that could be rolled up and slid inside a blade tube.

The screen could be used to display the blade effects.

Thus giving us unparalleled options in blade design.

Happy Birthday!

Happy birthday!

An actual screen would be the holy grail of blades…I bet the minimum order is a few thousand units though for something like that.

Thank you @NoSloppy @mcarcher.

Been spending my day chilling out and watching the bad batch

Yes the graphics would be stunning.

Not sure how bright it would be though.

so been searching for what the market is currently offering with regards to flexible screens.

https://www.alibaba.com/product-detail/6-42-inch-flexible-amoled-lcd_1600107649100.html?spm=a2700.details.0.0.56eb6d9bQN1i1k

this is about the the best I could find.

the tech is there to make it work but would take some serious financial backing to get this idea off the ground.

I figured out how to print the helical cores on their side: use a break-away stand along a narrow edge.

Basically, I created an axis between a point on both ends, then made a tangent plane to that axis, then an offset plane from that tangent plane. After that, I made a rectangle sketch on the offset plane, and used the loft command to join the rectangle to the edge of the core.

I’m going to test a print and see how it works.

going back to your post here ![]() when i broke the twisted tri core i was thinking of printing it again, but test its strength with all the strips attached.

when i broke the twisted tri core i was thinking of printing it again, but test its strength with all the strips attached.

as you said, it should be more stable that way.

i have a few spare off cuts so will do just the 1 section of about 100mm.

i will also print a more aggressive twist as well to see how well the strips cope.

i theory a thinner strip might not have as much stress put on it when it is twisted around the core as the outer radius would not be as high as with the wider strips… so if my strips can handle it then i should not see any reason that the thinner strips would have a problem.

wow, nice job!

so are you going to do a full length test or just a shorter version?

Thanks!

I’m going to re-build the strip I tested yesterday, but this time with helical cores and sanded pixels.

I’m about halfway done sanding down the strips, while they are still on the old core. I’m going to do a test to compare shadows before I finish it.