I am in need of a (at least) 10 pin chassis connector. It is a cross guard, so one main blade, 2 small blades and 2 buttons, all past the connector.

I need: btn1, btn2, gnd, d1, d2, d3, led-1, led-2, led-3, batt+

I have found 3 options:

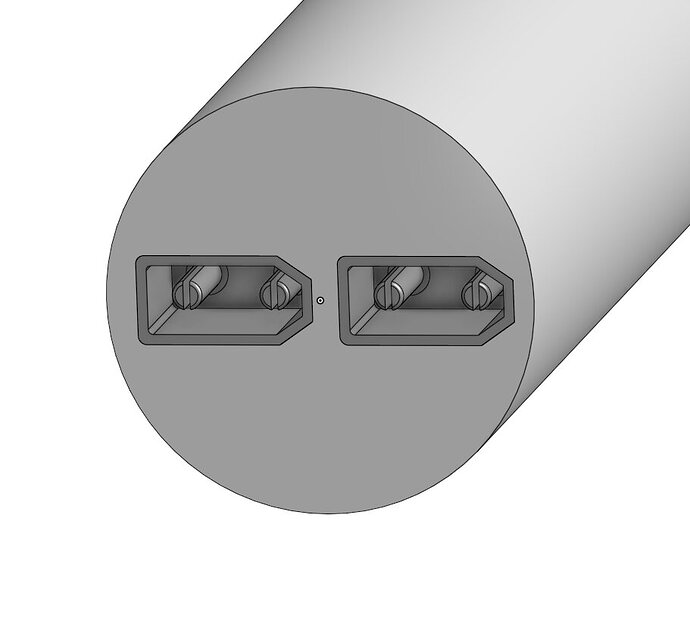

1 - TSM removable chassis connector

https://www.etsy.com/listing/1531048924/tsm-removable-chassis-pcb-connector-set

This one is a bit strange, many pins, and some don’t make sense, four 5v pins?

The seller says that it is rated up to 15 amps, but I am skeptical due to how small the pins must be. I could tie a few together to make sure there is more copper for the high amp lines.

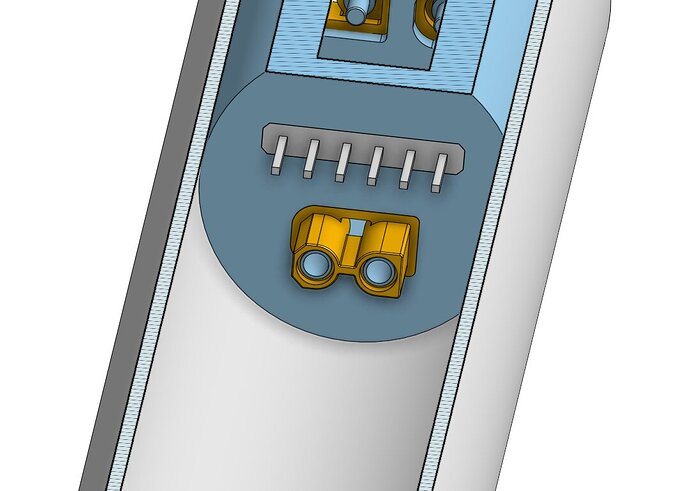

2 - Shtok 10 pin chassis connector

I would be using each pad/pin for discrete use, so not really how its intended. I would have to get a hold of one to test. It is rated to 15 amps as well, but that appears to be if you use both sides for positive and negative bring down the connection count to 8.

If I used “shared power pins”, I guess that would bring my connection count down to 8. btn1, btn2, gnd, d1, d2, d3, batt+ and all led-. Would that work?

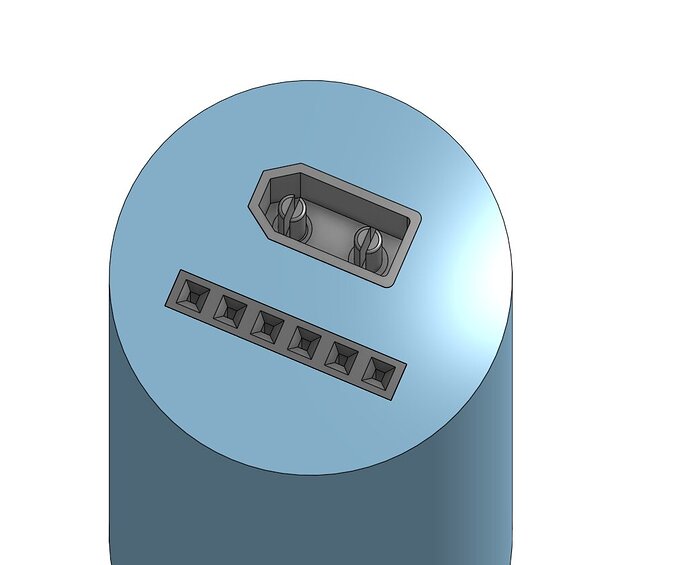

3 - 89sabers chassis set

https://www.aliexpress.us/item/3256806756924385.html

This has 13 pins but doesn’t list the amp rating. The pins appear pretty beefy and are directly connected to the solder joint. It’s what 89sabers uses for the same situation in their own sabers, so I assume it would accomplish the amp rating.

4 – design my own? I like this idea, as I like to design things and implement them, but I have not done pogo pin pcb’s. I think I could figure it out.

Can I get your opinions on these ideas? Has anyone made a chassis with 10 or more removable pins?

I found this post Best way to solder a small 10 pin connector - #10 by Maff76 which appears to have at least 10 or 11 (depending on how many oins are + and -), but looks a little precarious to me.