If data2 is not hooked up it is not going to work. Are you sure you are uploading what you think is uploading ? You can try to remove the first “S” from the first “Styleptr” in your config. If you verify and there is no error, you are not modifying the correct file. If there is a compile error (as it should), then great, put the “S” back because you are changing the correct file.

Did your blade and pcb light up when you did the blade length finder procedure?

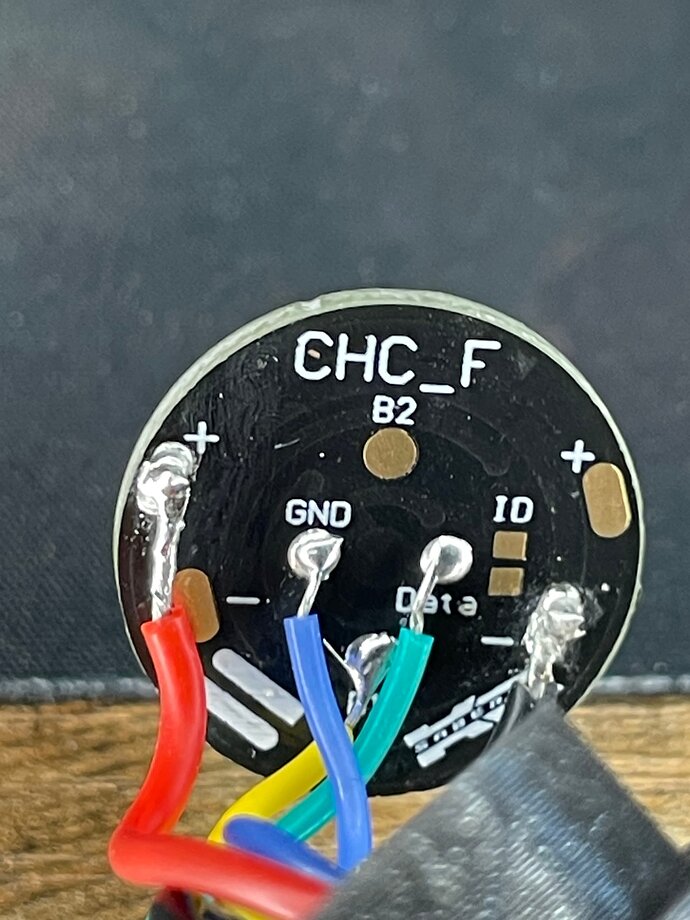

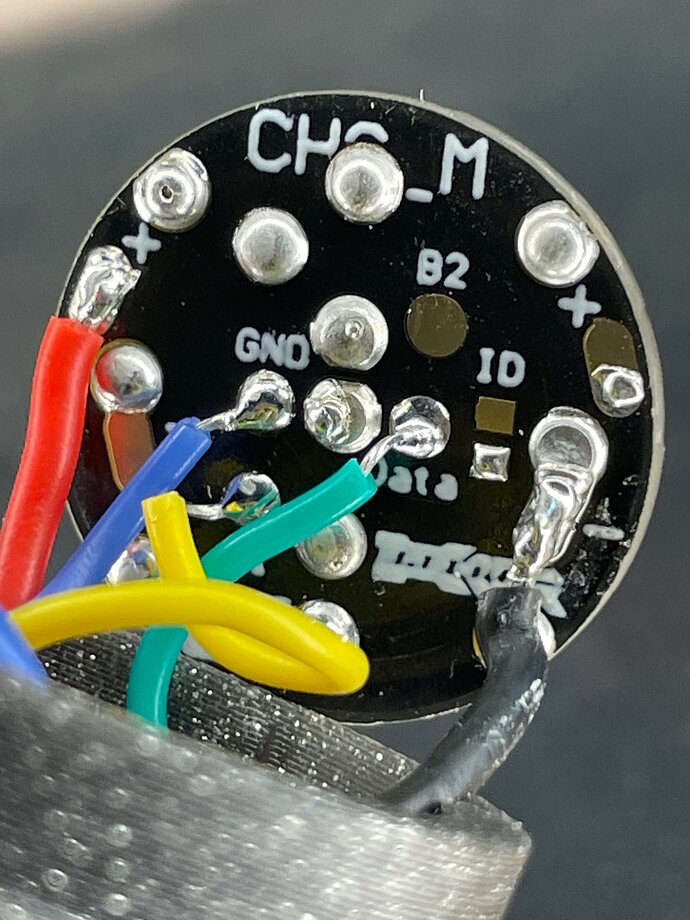

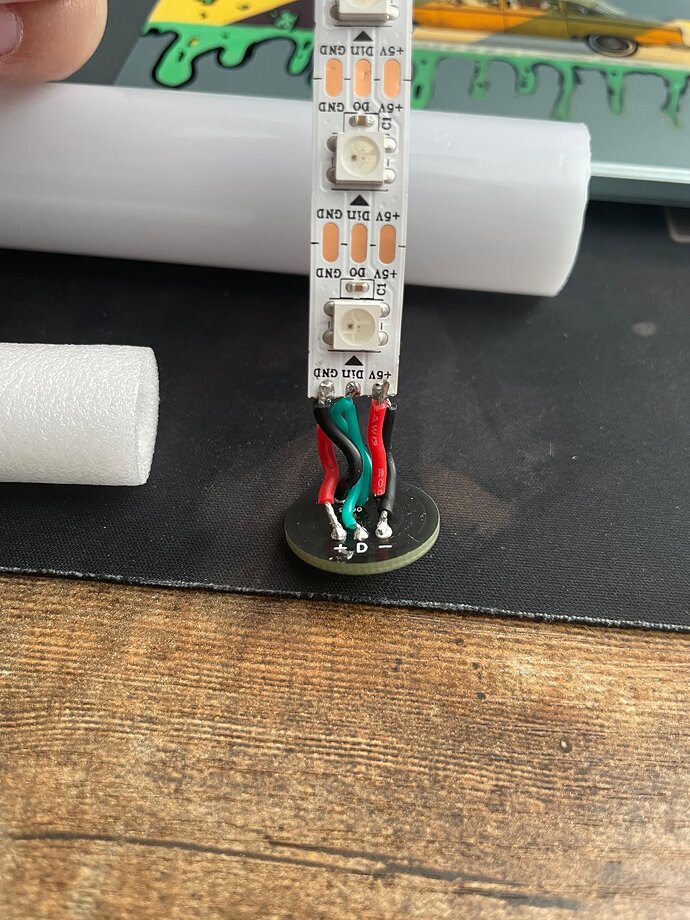

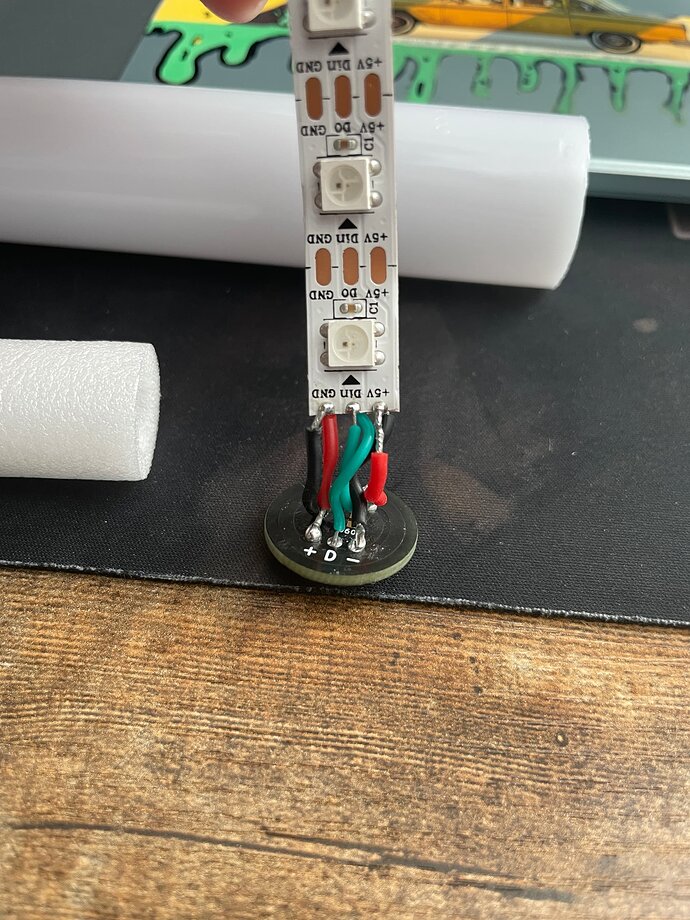

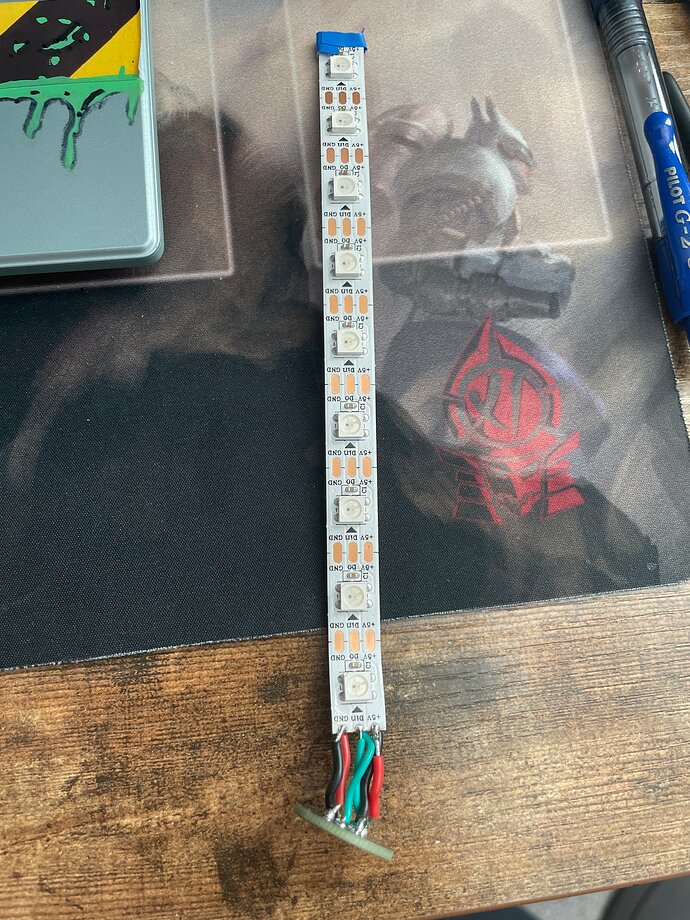

Clearly from the photo, it is all hooked up to data1 (bladePin) so you can forget trying blade2Pin.

In this one the numbers are wrong

But this one should now work using bladePin (data1) and the correct numbers:

{ 0,

SubBlade(30, 141, WS281XBladePtr<142, bladePin, Color8::GRB, PowerPINS<bladePowerPin2, bladePowerPin3> >()), // this is your main blade with 112 leds

SubBladeWithStride(0, 29, 2, nullptr), // this is your pcb part1 with 15 leds (1 out of every 2 starting at 0)

SubBladeWithStride(1, 29, 2, nullptr), // this is your pcb part2 with 15 leds (1 out of every 2 starting at 1)

CONFIGARRAY(presets) },

};