Hi All,

I used a proffie to control LEDs on a marching band bass drum, and as such, there is no hilt, nor speaker. Each side of the drum is a single LED strip (5m 12V cut in half) and I have a Saber Armory dual pixelswitch as my two switches. I have programmed four blades such that each side is a blade, one pixel on the switch’s strip is a power indicator, and the rest of the LEDs on the switch are an indicator or a preview of the blade style. I can’t see the lights when I am wearing the drum, so it’s helpful to see the font I’m on before I turn them on.

I think I know how many LEDs each strip is, but I wanted to use LengthFinder to verify that. Since I cannot hear what the style says, and nor can I “rotate the hilt” easily, how can I modify the LengthFinder.h code (or another file) to make this work for my purposes?

Thanks for the help.

Mike

1 Like

That’s pretty cool.

If you are able to use the serial monitor, then you can use the “var” command to set the length for the LengthFinder. Just like, type in “var 42”. Just note that the actual length will be one higher than the variation, so if you type in “var 42” and the last led of the string lights up, then the number of LEDs in the string is actually 43. (You’ll also see this in the serial monitor as the length finder will print out some values.)

Thanks Prof. I’ll give that a shot.

I’m getting a bunch of “whut” when I try different variations of “var” commands in the serial monitor. I don’t have disable-diagnostic-commands enabled. Any more ideas?

Do you have DISABLE_COLOR_CHANGE ?

I did. Once I disabled that, it worked just fine.

Thanks again for the help.

I love ‘off label’ proffie projects. Do you have a little video clip? Nicely done!

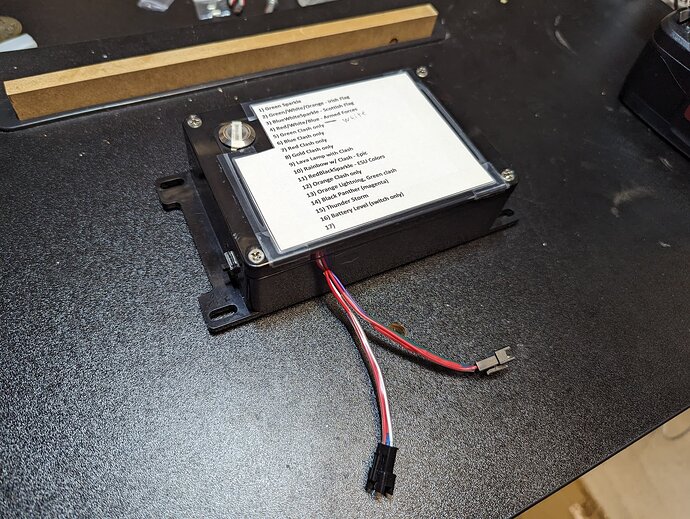

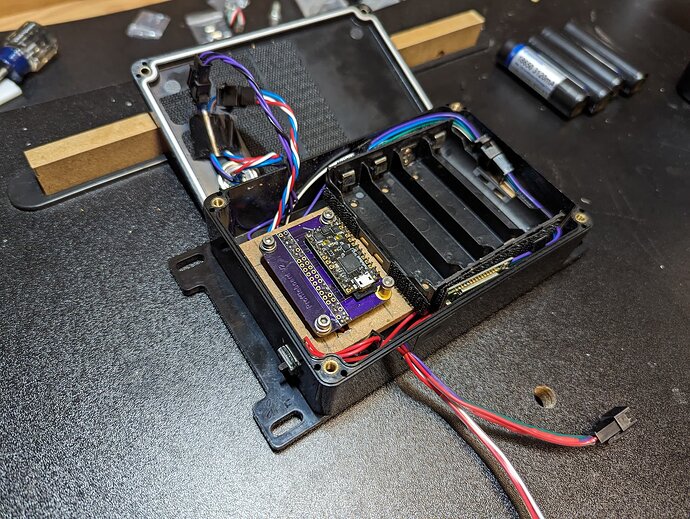

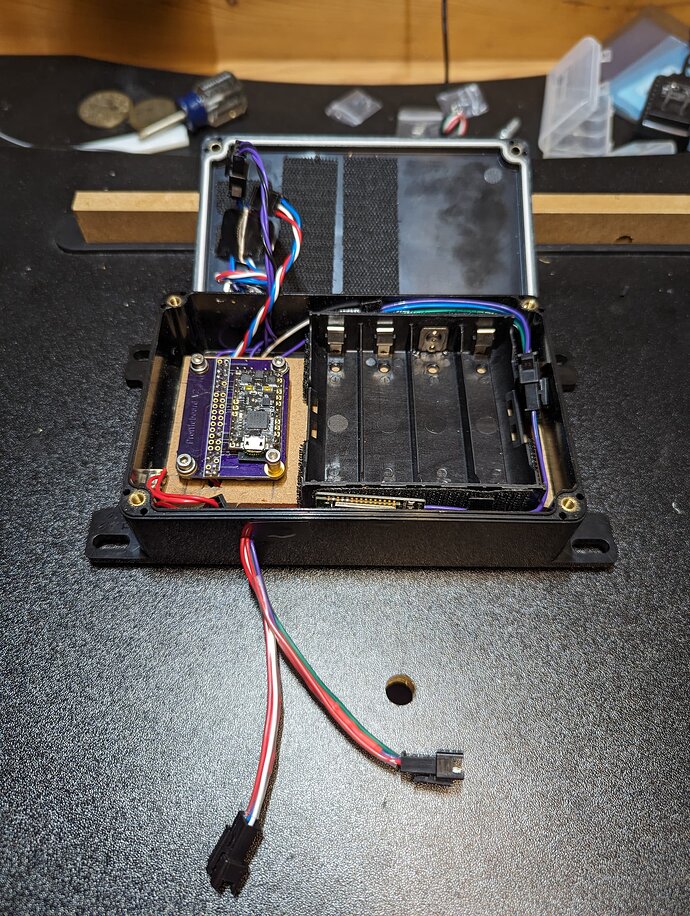

Here are some pictures of the control box and installed on the drum:

2 Likes

And here is a YouTube link for a performance we did in our hometown last September:

3 Likes

Trust me when I say that the video loses sync with the audio sometimes, so we’re not as bad at timing as it looks on the video.

Are you kidding  ? Totally exceeds expectations!

? Totally exceeds expectations!

Fantastic work and a great performance!!

Very cool.

Is there anything you wish this would do that you were not able to do?

Do we need a “drum” prop file?

I assume you mean what can the Proffie do/become, but my next idea would be to make button actuators that I could put into the mallets instead of needing to push buttons on the control box. If you can point me to something like those that I could try out, I’d appreciate it. They’d need to be wireless and as small as possible.

Regarding a Prop file, the one I used is a pared down version of the saber.h prop file. It didn’t need to be anything more complicated than that for what I made.

To be honest, I chose a Proffie because I had an extra one after messing around with sabers. The only functionality that I actually uses is the accelerometers and LED-driving capability. I have a Bluetooth module installed, but I don’t use it. I put it on as a backup in case I couldn’t change fonts or turn things on /off while in the middle of a performance, so I had my wife standing by connected via Bluetooth incase I needed her to take control. Turns out it worked well, so if I were to remake it, I probably wouldn’t use the Bluetooth functionality.

Speaking of Bluetooth, how about the possibility of uploading the OS via Bluetooth instead of hard-wire? Not needing a hard-wire connection to upload changes would mean that the control box could be fully enclosed and not need to be opened. As I have it now, I need to open the box in order to make changes, then close it back up to test it on the drum. I know I can just use a really long USB cable, but if you’re asking about future upgrades, a wireless upload would be nice.

Option #1: A small bluetooth camera trigger button, paired with a raspberry pi W or similar (which would then send a command to the proffieboard over serial or USB)

Option #2: It should be possible to make an ESP32 talk to the BT chip you already added to the box. You could use something small like the Adafruit QT-PY. If you can make the connection work, you could just send commands like “next_preset” directly over BT.

Option #3: Place a magnetic sensor in or near the control box (reed or hall effect) put a magnet in the mallet. It’s not actually wireless, but now you can “press” the button by putting the mallet on the control box. If you need multiple buttons, you could have multiple sensors placed at different points on the drum or control box.

The STM32 bootloader actually supports uploading program over serial. I’d have to check if it’s allowed on Serial3 or not (which is the serial port we normally use for bluetooth.) If it does, this might be relatively simple to implement.

2 Likes