I tested all the boards before assembly, so they were damaged during stacking.

In hindsight, I would have put traces and via’s on the other side of the LED pads, to keep them from peeling. I would also have purchased some lower grain size solder paste. But yes, the idea is sound, it is just a tremendous amount of time to assemble.

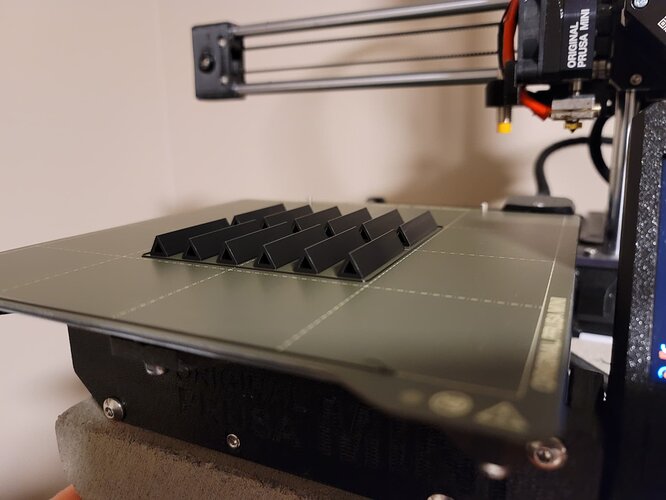

So I printed 24 of these:

1 Like

After a lot of searching online I did find some aluminium extruded triangle tubes and in the right size, but at 500kg minimum order it was way out of my league.

I did think that the 3d printer would come in handy yet again and print some triangles with joiners.

Are you sure you haven’t hacked my home security

But in all seriousness now, its a good idea, would you do it in PET or PLA?

I’m not sure that it’s all that sound if you can’t repair it after it’s assembled.

1 Like

Haha we do seem to think along the same lines!

I printed them in black PLA. The last 6 ran while I was at work today, so I might get a chance to assemble tonight.

My idea is to space them out with maybe 20mm between each support, in order to allow some flex in the strips.

1 Like

interesting, but wouldn’t the flex cause possible strip failure?

i mean, as they flex wouldn’t it cause wrinkling on the strips?

i know why we need a certain amount of flex but localizing it might not be a good idea.

maybe PLA would be good as it will become pliable at temps of 60 degrees. this might give it some flex if the whole thing was glued together?

That’s a good point…I had not really thought about the repeated stress or wrinkling.

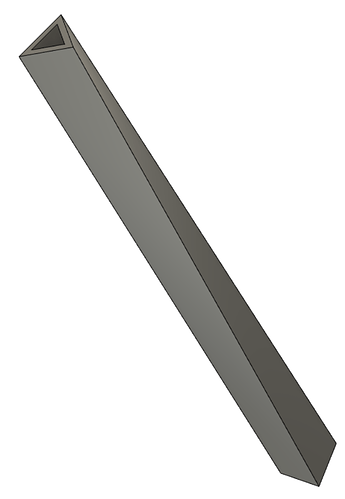

I guess putting them end to end will work too. I think printing some longer ones with thinner walls to allow more flex will work better. I was planning on putting some clear PVDF heat shrink tubing over the whole thing.

yes that was my thoughts on it when i was going to do it but just didn’t get round to it. (got side tracked as usual)

the thinner walls would definitely help to allow more flex but i wonder if the heat inside would cause the PLA to buckle and deform? this was why i asked if maybe PET or PET-G might be better?

How hot does it realistically get in there?

that is one of the mysteries…

technically the surface temp on the back of the “PCB strip” could reach temps of about 70+ degrees at full brightness on white, but not many blades would run that for long periods.

plus most users tend to steer away from white blades because of the power consumption.

so based on that… maybe about 30 - 40 degrees?

i mean im only being subjective at this point.

i know green creates a lot of heat on its own.

other factors would be how long the blade is ignited for

so diving into it, would a 0.8mm wall thickness be to flimsy?

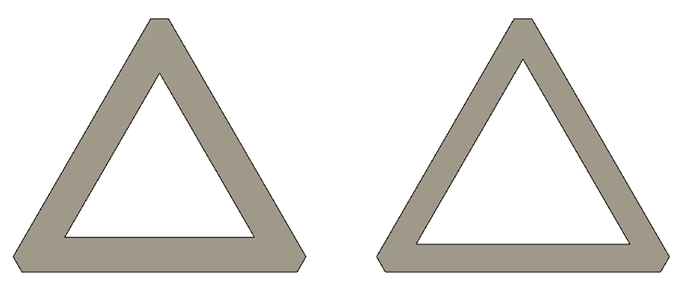

I’m not sure if it would be or not. I have a 0.25 mm nozzle set up in the printer, so a 0.8 mm wall would be three layers, which might be enough. I think I am going to do 1.0 mm. Here is 1.0 vs 0.8:

1 Like

Wait a minute, could you do a really shallow helical pattern on the sections, kind of like the picture I posted of the rod earlier with strips wrapped around it?

Except, with this, the strips would be flat against the surface, which would put less stress on the solder joints.

1 Like

i see you just dropped a bomb!

i will jump on it a see what it looks like on fusion.

but yes that would work very well

say 60 degree twist every 300mm?

That sounds about right. The loft command should work for this I think.

It’s also possible to make the triangle slightly smaller than the width of the strips, and let one edge stick out a couple of mm on each of the strips. At least that worked quite well for the quad-blade I made with 7.2mm strips around a 6mm dowel.

Also, to make the structure lighter, just make hexagonal holes in it.

3 Likes

that’s a good idea, both in size and with the holes.

the holes might add more flex to it too

just tried the loft command and got some interesting results, trying it with loft using rails next

Something like this?

I like @profezzorn 's idea of having one side smaller. It gives that much more diffusion. I don’t really know how you would print this though, unless it is standing up?

1 Like