I own no hilt, I bought a chassis back in June for my first Proffie built/first attempt at a saber/first anything prop for Star Wars (other than a few T-shirts & my DVD/BLUE-RAY collection), but I damaged it, then broke it to extract My Precious Proffie board and most of the electronics. Now I am working on some monster (with plenty of wire space) 3D printed chassis loosely inspired from Goth3D designs and any free stl’s I can find to hold “My Precious” (I know, I am repeating myself, but so far I only got one).

Once done it will be a cross-guard with a Tsuba that has greeblies inside of greeblies, probably at least half a meter long (the chassis, not the tsuba) and a mighty dangerously looking pommel, that will never fit in any “real” looking metal hilt (which I still would like to come up with a design for it - but don’t hold your breath, it will be a very long while).

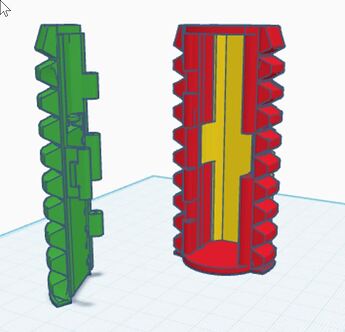

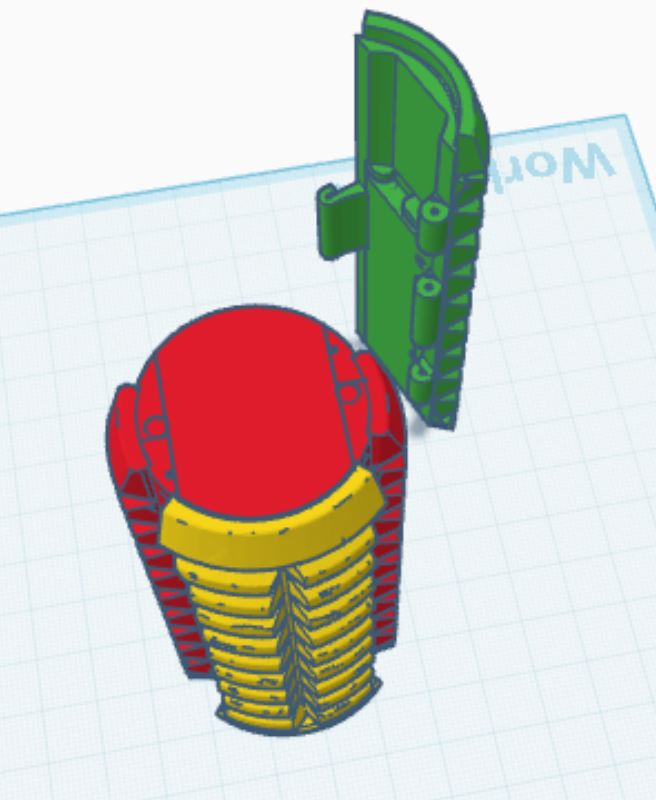

Attached are two photos (from a few weeks back) from (now)

mostly discarded, first iterations or just plain badly 3D printed parts I come up with (I started my 3D printing adventure in December) that will be the base for my saber.

It will mostly be dark red (my favorite color). No I am not building an Iron Man prop (my sons like to tease me with that).

I think now, I have all the designs in mind, except one section: the part that will hold the main electronis:

- My Precious (Proffie board)

- Oled

- BlueTooth

- USB-C charging board

- & the reverse polarity protection board

I am looking for designs inspiration for the “internal” pressure-fit that can hold all those boards. The external is inspired from a “grenade” thin neck with at least two doors for easy access for soldering/de-soldeing/re-soldering (front and or back)

I am just a bit stuck on how to match my vision of what the inside should be for fitting the outside. And I need to allow for the three metal rods (3mm each) to hold it all together and not interfere.

I know it is all PLA (and 3 metal rods - not threaded - and some superglue). It will only be for “air fighting” and very mild spinning (plus my blade tube is acrylic - so no contact allowed).

I am looking for ways to link my outside of the electronic chamber to how the inside should be.