Thanks alot!

That’s the mapping i was looking for

Time to dive a little bit deeper into the possible configurations while waiting

for my saber parts to arrive.

Starting config would look something like this with the default font download before getting deepter into fonts and styles.

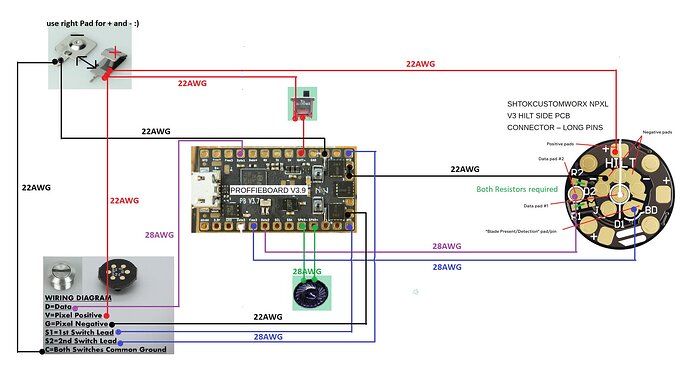

Was a little bit confused why the config generator starts with NUM_BLADES 3 with only the “illuminated pcb” selected (default v4 neopixel pcb config should be 2 blades right? (main + pcb pixel) and in my v2 config 1 Blade because they should be in parallel + 1 Blade for my pixel switch (6pixel).

#ifdef CONFIG_TOP

#include "proffieboard_v3_config.h"

#define NUM_BLADES 2 //v2 neopixel pcb = 1 blade , pixelswitch = 1 blade

#define NUM_BUTTONS 2

#define VOLUME 1000

const unsigned int maxLedsPerStrip = 144; //To be specified when i build a blade

#define CLASH_THRESHOLD_G 1.0

#define ENABLE_AUDIO

#define ENABLE_MOTION

#define ENABLE_WS2811

#define ENABLE_SD

//#define SHARED_POWER_PINS not in v2 neopixel pcb config

#define BLADE_DETECT_PIN blade5Pin

#endif

#ifdef CONFIG_PRESETS

Preset presets[] = {

{ "TeensySF", "tracks/venus.wav",

StyleNormalPtr<CYAN, WHITE, 300, 800>(),

StyleNormalPtr<CYAN, WHITE, 300, 800>(), "cyan"},

{ "SmthJedi", "tracks/mars.wav",

StylePtr<InOutSparkTip<EASYBLADE(BLUE, WHITE), 300, 800> >(),

StylePtr<InOutSparkTip<EASYBLADE(BLUE, WHITE), 300, 800> >(), "blue"},

{ "SmthGrey", "tracks/mercury.wav",

StyleFirePtr<RED, YELLOW, 0>(),

StyleFirePtr<RED, YELLOW, 1>(), "fire"},

{ "SmthFuzz", "tracks/uranus.wav",

StyleNormalPtr<RED, WHITE, 300, 800>(),

StyleNormalPtr<RED, WHITE, 300, 800>(), "red"},

{ "RgueCmdr", "tracks/venus.wav",

StyleFirePtr<BLUE, CYAN, 0>(),

StyleFirePtr<BLUE, CYAN, 1>(), "blue fire"},

{ "TthCrstl", "tracks/mars.wav",

StylePtr<InOutHelper<EASYBLADE(OnSpark<GREEN>, WHITE), 300, 800> >(),

StylePtr<InOutHelper<EASYBLADE(OnSpark<GREEN>, WHITE), 300, 800> >(), "green"},

{ "TeensySF", "tracks/mercury.wav",

StyleNormalPtr<WHITE, RED, 300, 800, RED>(),

StyleNormalPtr<WHITE, RED, 300, 800, RED>(), "white"},

{ "SmthJedi", "tracks/uranus.wav",

StyleNormalPtr<AudioFlicker<YELLOW, WHITE>, BLUE, 300, 800>(),

StyleNormalPtr<AudioFlicker<YELLOW, WHITE>, BLUE, 300, 800>(), "yellow"},

{ "SmthGrey", "tracks/venus.wav",

StylePtr<InOutSparkTip<EASYBLADE(MAGENTA, WHITE), 300, 800> >(),

StylePtr<InOutSparkTip<EASYBLADE(MAGENTA, WHITE), 300, 800> >(), "magenta"},

{ "SmthFuzz", "tracks/mars.wav",

StyleNormalPtr<Gradient<RED, BLUE>, Gradient<CYAN, YELLOW>, 300, 800>(),

StyleNormalPtr<Gradient<RED, BLUE>, Gradient<CYAN, YELLOW>, 300, 800>(), "gradient"},

{ "RgueCmdr", "tracks/mercury.wav",

StyleRainbowPtr<300, 800>(),

StyleRainbowPtr<300, 800>(), "rainbow"},

{ "TthCrstl", "tracks/uranus.wav",

StyleStrobePtr<WHITE, Rainbow, 15, 300, 800>(),

StyleStrobePtr<WHITE, Rainbow, 15, 300, 800>(), "strobe"},

{ "TeensySF", "tracks/venus.wav",

&style_pov,

StyleNormalPtr<BLACK, BLACK, 300, 800>(),

StyleNormalPtr<BLACK, BLACK, 300, 800>(), "POV"},

{ "SmthJedi", "tracks/mars.wav",

&style_charging,

StyleNormalPtr<BLACK, BLACK, 300, 800>(),

StyleNormalPtr<BLACK, BLACK, 300, 800>(), "Battery\nLevel"}

};

Presets no_blade_presets[] = {

{ "TeensySF", "tracks/mars.wav",

StyleFirePtr<RED, YELLOW, 0>(),

StyleFirePtr<RED, YELLOW, 0>(),

"no blade" },

};

BladeConfig blades[] = {

{ 0, WS281XBladePtr<144, blade2Pin, Color8::GRB, PowerPINS<bladePowerPin2, bladePowerPin3> >(),

WS281XBladePtr<6, bladePin, Color8::GRB, PowerPINS<bladePowerPin5> >()

, CONFIGARRAY(presets) },

{ NO_BLADE, $BLADES$ CONFIGARRAY(no_blade_presets), "nb_save" }

,

};

#endif

#ifdef CONFIG_BUTTONS

Button PowerButton(BUTTON_POWER, powerButtonPin, "pow");

Button AuxButton(BUTTON_AUX, auxPin, "aux");

#endif