Yes, I know they are called nunchaku (did you you the u is a swallowed vowel, so that in Okinawan it’s silent?).

First a disclaimer: I am a resident of NY state, USA, where nunchaku were illegal for quite some time. More info here on what changed and why this project is now possible. The laughing monk in this piece was my coach for about a year.

So if you decide to connect two sticks with a string, it’s on you to break neither the law nor your front teeth.

The idea for proffie chucks is certainly not new. It would have been a good fit for the hybernating M2, as pointed out by Profezzorn a while back. And I ofcourse considered other solutions, like the very cool PixelBlaze PICO V3. But proffie still reigns supreme with overall form factor and OS, even without dotstar/pov capabilities.

There are ofcourse light saber nunchaku on the market, but I don’t like their design pattern even if they are very in universe. They usually have two small hilts connected by a chain, with the blades pointing away and down. Shout out to Jedi Shaggy. We’ll leave the flow toys out…they are cool but are all blade. That’s not very Star Warsy.

So in order to understand what I wanted, I bought cylindrical nunchaku from USA Nunchaku to try and figure out how they are used. Traditonal sticks are octagonal, but saber blades are round.

The summary is that if you grip near the top, you are doing art, and if you grip low, you’re doing martial. I practiced most mornings for about 2 months, and now they’re part of my regular training. Recommend! Great upper body workout, and very fun. This company makes very high quality tools.

At the dinner (read: drinking) table my wife and I mulled over some designs:

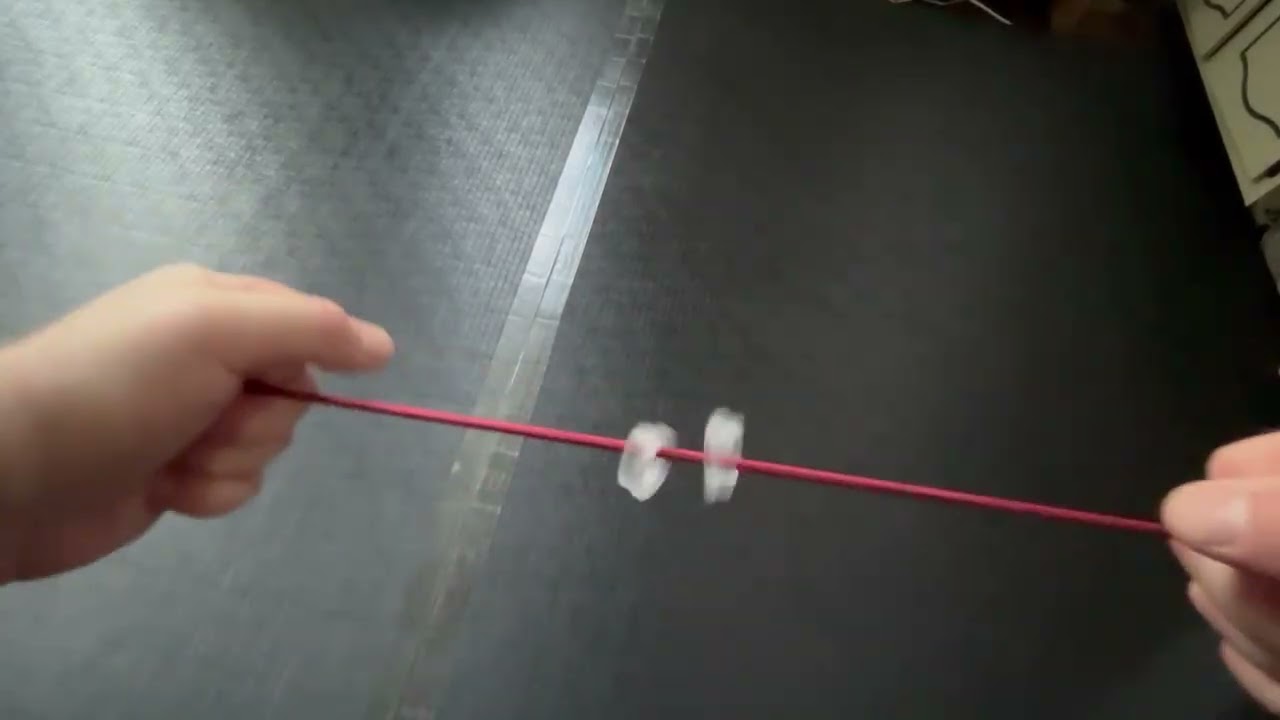

There are some real issues with making these things, mainly that I wanted a low grip to keep it martial. A low grip means a killer amount of centrifugal force. Here are the chucks I received. There are three lines of paracord connected them, embedded in the wood. I choose “jedi” as the cord color, ofcourse.

So my big fear is a chuck flying away, or swing stress pulling on the components. They need to be very, very secure.

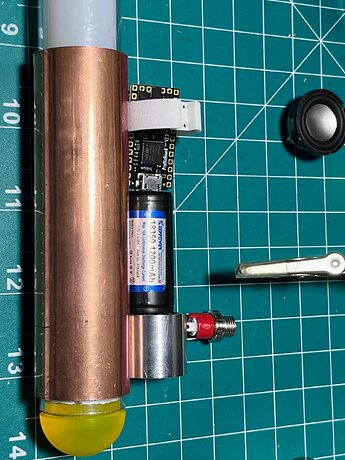

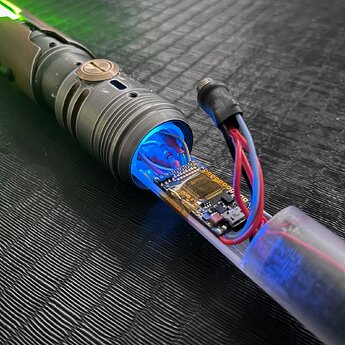

This means no wiring btw the blades. Too stressfull, literally. So this project requires two proffies, IMO. The wooden (ash) sticks are extremely light, but get VERY heavy when you swing like you mean it, which meant an 18650 in each stick would be a death wish. Also, the top of the blades near the cord would have to be much stronger than I anticipated.

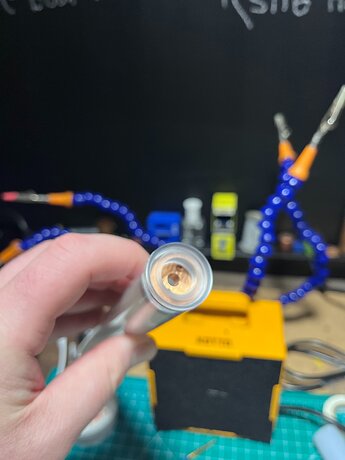

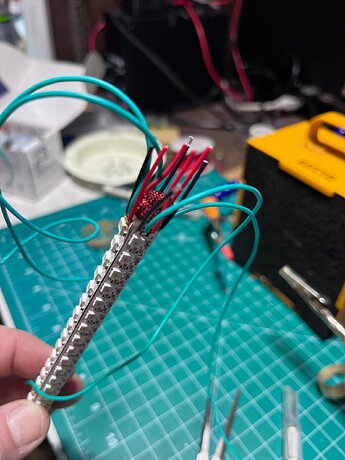

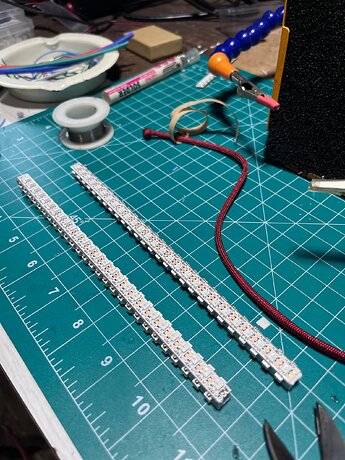

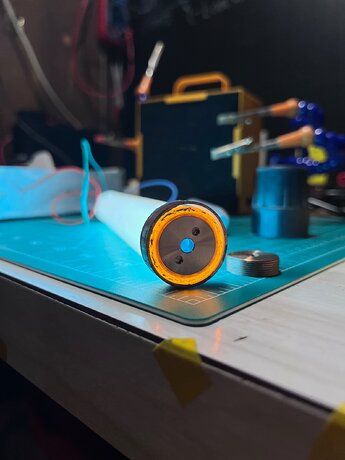

After several frustrating attempts at a top deisgn, including using all kids of bearings and caps (fishing bearings came close), I realized a 7/8 tri-cree heatsink under a pcb holder could give me the look and stability needed.

Like so:

Only testing will tell though. The triple paracord loop also showed me that bearings are not really needed. You can whip figure 8s and there’s not real loss of motion from the rope being stable where it hits the stick.

So to conclude this intro to the build, I’m ready to set up the basic blades and have found some other solutions that I’ll share. If I was making these for the screen, I’d make empty beskar casings that could be used as a blunt weapon with the kyber blade inside for blocking. Then you could pull of the case and start chopping up the Knights of Ren with the bare blade. But in reality, I want the thinnest, lightest chucks I can make, with a compromise between Star Wars in universe blades and the infinite blade of flow sticks.

And a final fun fact from my research: many of Bruce Lee’s famous moves are not possible with regular nunchaku, particularly his armpit stall. He modified his screen chucks so that the chain was the same length as the sticks…12 links instead of the 3 or 4 you’d find for martial arts practice. Clever.

More soon as summer project season approaches! Thank you for checking out my build log!