I’ve tried Fusion360 on my MBP and it’s a buggy mess. Giving FreeCAD a try, but I’m also new to CAD so kinda overwhelmed…

I use OpenSCAD.

It’s way different than most cad programs in that you essentially just type everything. It’s also rather primitive in how modelling works compared to a modern cad program, but it fits my sensibilities as a programmer well.

If it was a few orders of magnitude faster, it would be really cool IMHO.

Really? On a mac? Howso? Are you on arm/M series or something?

This is genuinely super surprising to me, lol… forgive my flabbergasted-ness

I used Fusion360 on macOS for years and it never gave me any issues. It’s gotten progressively more annoying with some of Autodesk’s, erm… architectural changes, but it was always functionally pretty decent at its job.

Only reason I don’t use it now is because I can use Inventor instead, and it runs on Windows, and Inventor is basically what Fusion is trying to replicate, but not cloud-based or with any of the limitations of Fusion. (It’s a lot more feature-rich and nice to use)

That sounds well out of my skill level!

Yeah, I’m on M1. The last straw was when the cloud saving bollocks shit the bed, losing a portion of my project. Before that it was constant weird visuals missing and things not placing properly or selecting.

Agh, well that’s unfortunate. All the visual stuff I’d almost guarantee is having to do with the Apple Silicon, which is, again, unfortunate. But yeah, losing work is always frustrating, it’s one of many reasons I detest cloud-based stuff.

Wonder if that’s instability because of networking APIs going through Rosetta or if Fusion really just has gotten that much worse… even when cloud stuff went out I didn’t have an issue with losing data because of the local recoveries. Obviously that’s not the case for you, but I find it interesting.

It’s supposedly the ARM64 version too.

Ah, I didn’t know Fusion had an arm release.

I’d imagine there’s still some fiddliness under the hood to make it work though, so it still isn’t super surprising, just disappointing ![]()

Yeah, doesn’t explain the crappy cloud saving going wrong. That crap should be optional, not mandatory.

100% agree. That’s what I really like about Inventor’s setup. I manage a local Vault instance and I get all the fancy PDM stuff (and then some) Fusion has, but it’s all local.

It’s like git for CAD, ha! (I know there’s other PDM softwares, but Vault is what integrates directly with Inventor and was pretty simple for me to setup, so I’m a fan)

I tried FreeCAD. Controls are clunky compared to free Fusion for me. Main issue I have with Fusion is how so many useful and sometimes necessary features are paywalled. But I haven’t had issues with crashes on my MBP (M2).

You should give onshape a try. It’s browser-based which has pros and cons, no big install to worry about. For free version All your designs are public which is fine for hobby and bad for business.

You still need modest GPU and CPU for rendering, but it’s surprisingly good. I never would have thought heavy 3D modeling in browser would work, but I love it so far.

I also tried openscad, as a programmer it makes a ton of sense. But to wrap my head around programming language driven parametric 3D modeling gets harder and harder as the modeling gets more complex. For super complicated designs with tons of components, a more UI focused program is very helpful.

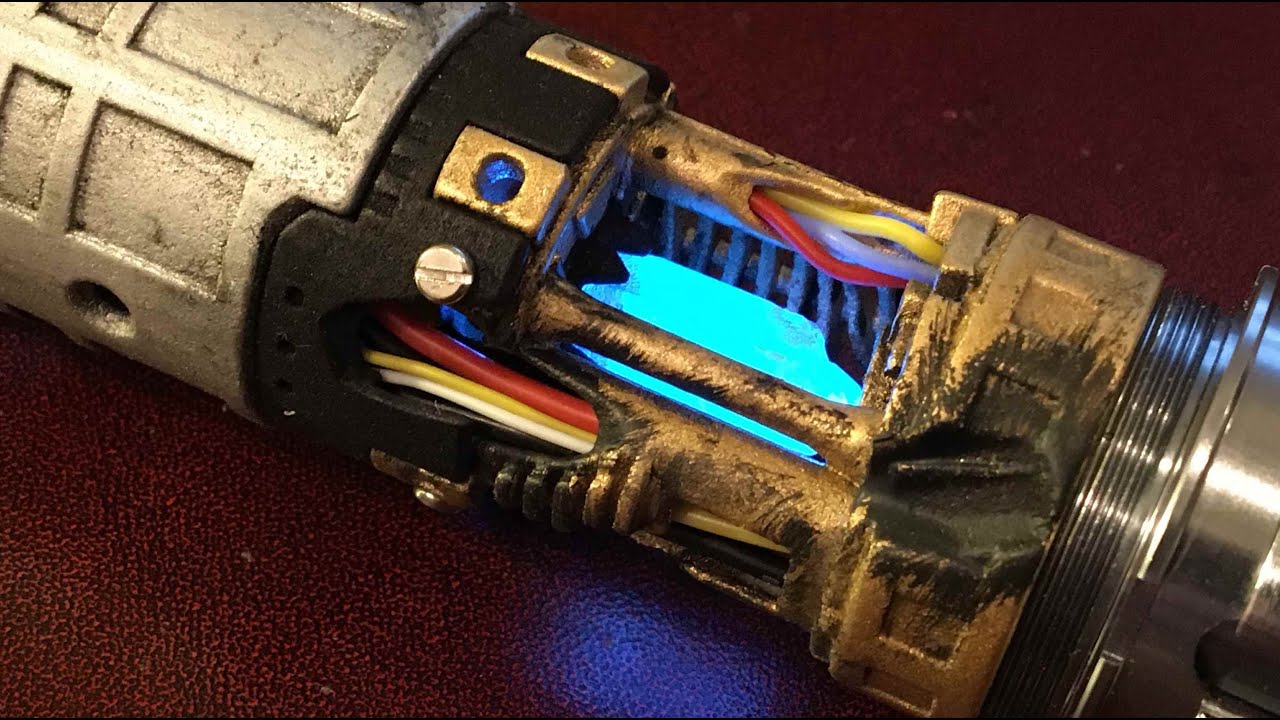

I’ve done two or three custom chassis and hilts so far, pretty neat. I think in one of my past posts you can see a screenshot from my last last design of how I modeled the button going through the hilts into the chassis. A little sneak peek of how nice it is to design in real cad (vs SketchUp that I was trying to use years ago).

As far as I can tell it’s very close to fusion 360 capability and feature wise. And no weirdness around locking and unlocking a limited number of models in the free version.

I dislike OnShape with a passion. Performance wise it’s abysmal (which is fine if you’ve got a proper computer and cycles to spare and aren’t doing anything complex and don’t plan to… but… what a waste. I also strongly dislike excessive waste), it of course requires a strong internet connection, and cloud based stuff to that degree I’m never a fan of…

The whole “making designs public” thing just feels really weird to me too. I dunno, I know people that use it, but I could never stand it. Fusion’s browser thing, as comparatively clunky as it was, always worked better for me and my team, it was just more reliable. For something that’s basically just a remote desktop session to work better than something that’s built from the ground up to be CAD in a browser was a hard nail in the coffin for me… and that was before they changed all the licensing things.

I almost hesitate to admit this given all the high-powered programs being discussed here, but all of my chassis have been produced using nothing more than Tinkercad - a free-to-use browser app that, as far as I know, has no limit on how many models you can have, doesn’t automatically make your designs public unless you tell it to, is quick and simple to learn and basically does everything I need it to. In the grand scheme of CAD, lightsaber chassis aren’t the most complicated things in the world, and Tinkercad seems tailor made for them. I dare say if I ever need to do more complicated CAD projects, I’ll run into its limitations, but so far it’s done everything I need. The biggest thing it lacks is any kind of proper rendering feature, but for myself, I’m happy to live with that.

Maybe it’s because I’m getting on in years, but I think many aspects of life these days are overburdened by too much complexity – from the audio systems I have to work with in my day job, to cars trying to second guess your every thought and ending up making life more difficult rather than easier. I’m all for keeping things simple.

All of that said, I admit my designs aren’t the most complex - not like Goth’s high end stuff. But I flatter myself they hold up pretty well.

Anyway I guess the point I’m making is that you don’t necessarily need super-complex tools to do half-decent work.

Here are a few examples - all done with Tinkercad:

![]()

Tinkercad comes up regularly. did you design the chambers with it? I always thought it was very limited in what it can do?

I like the idea of sticking to open source software, but honestly it is usually a struggle to get what you want from it. I do use Firefox, LibreOffice, Audacity etc. My dream was to use Blender but that’s a steep learning curve.

Yes, every part of every chassis I’ve done was done in Tinkercad. You’re right in that it has its limitations, and I dare say if you’re doing huge volumes of work, then it’s probably slower than more high end alternatives. I also tried Blender, but as you say, that’s quite a beast and there’s a lot to learn.

My rule of thumb is to use open-source, or software I can buy.

(Not rent, not subscribe to, not “buy a license for a year”)

Any software that lives in the cloud, or rely on the cloud to work is out.

Any freeware that could change it’s licensing tomorrow is out.

Any software that could do a bait-and-switch on me is out.

For cad, this limits things quite a bit unfortunately. AFAIK, the only “real” cad that is actually open-source is FreeCAD. If I needed a “real” cad, I would probably try pretty hard to use FreeCAD. (This might happen one day, because I have a semi-functional mini CNC mill that I would like to do some things with…)

I also like to use OpenSCAD, but it does not have exports to STEP. Luckily FreeCAD can be used to convert it to STEP:

I don’t think I’ve ever needed to convert to STEP. What do you use that for?

If want someone to machine something they usually don’t want STL. I used JLCPCB to machine an aluminum part. Also, OSH Cut will cut aluminum, brass, or steel tubes with a STEP file.

I got some 1.500" OD x 0.058" Wall x 1.384" ID aluminum tube from OnlineMetals. I plan to build a hilt out of the tube since it is easy to cut, but I need some thing to get 1.384" down to 1.00". I had done this once with a brass sink tube and blade holder from Custom Saber shop, but brass is harder to work with than aluminum. I designed a coupler with 6 holes, 4 to connect to the tube and 2 to hold the blade. The part is about 2" long.

Anyways, it cost $120, including shipping, for 6 of them. At that that price, it is about the same cost as something from Custom Saber shop, but this something they don’t have.