This idea might need a drawing, but I’m too lazy to make one right now…

The idea is to use a small pin, to punch a hole through a layer of solder paste to make one small, precision deposit.

I was thinking that you could have a metal part, sort of similar to a water block for water cooling, smaller, and with only one connector. That connector would connect to a spring-loaded solder paste syringe to feed solder paste into it. The top and bottom of the metal block would have a small (0.5mm?) hole drilled into it, through which a small pin would fit. The inside space in the metal part would be fairly thin, like maybe 1mm, maybe even less. The idea is that by moving the pin up and down, you can feed a small amount of solder paste out through the bottom hole. That solder paste would be on the top of the pin, so you could deposit or smear it on to a circuit board. As long as the pin is going all the way through, there would be no leaking, and since the hole is very small, the spring would probably not be strong enough to cause much leaking even if the pin was left in the “up” position.

The “up” position should probably have an adjustable stop to only let in a small amount of solder paste each time. The device could be operated manually, similar to a pen, or it could be connected to a servo, motor, or magnetic actuator. (Probably a servo, as that would allow for some precision adjustments while not being fast and jerky.)

Now for questions: Does anything like this already exist? Or something similar to that could be easy to modify for this purpose?

It’s possible that it would still just become a smeary mess of course, but I feel like a design like this could be effective in dealing with the high viscosity of the solder paste.

1 Like

I might be able to make this in a regular syringe.

I can use a 27AWG tip, which has a 0.21 mm inner diameter.

I can then get a 0.2mm spring steel rod, and thread it all the way through the plunger and in to the tip. I’ll probably need some sort of guide thingy to make it go back in the tip when it is pulled out though… I might be able to just bend the spring steel wire back and into a loop to make it easy to operate with one hand. (stick a finger in the loop and move it up and down to operate.)

Or, this might work:

All I have to do is to drill (or melt) a 0.2 mm hole in the back of the elbow joint…

Update/new idea:

So I’ve been thinking about this for a while, and it recently occurred to me that the solution might be to use two pistons.

Basically, you have a cylinder, a mm or two in diameter, and you have a piston at each end controlled by a servo. There is a place where solder paste enters the piston, and another place where the solder paste exists. These two holes are off-center, sort of like this:

| | |

______| V |_________________________________________

___________________________________________ ______

| | |

| V |

The two pistons (which come in from the left and the right) can then move in unison over to the input, expand the cavity in between them to suck in solder paste. (The supply will need to be under pressure to make sure it gets fed in properly.) Then move over to the output and squeeze to push solder paste out. Since solder paste is a liquid and incompressible, the amount should be perfectly controlled.

The small piston size means that you can get high pressures with little force, which is helpful to move the thick solder paste move.

Btw, it seems that professional solder dispensers use something called an auger valve to do this, but that seems harder make at home, and the pro ones are expensive.

Found a better picture:

The pistons would come in through “in1” and “out1”.

(The pistons would just be solid metal rods.)

Originally I was thinking that this would be made up of tubes, but it might be simpler to just use a block of aluminum or something and just drill the required holes. I would need some way to attach a syringe to in2 and a tip to out2 though.

With a small steel luer nozzle, capillary effect should keep the device from over extruding–you could possibly modify the existing syringe style solder paste dispensers to meter a specific movement of the plunger–that’s how multi-dose drug pens work.

I find that to be super difficult. The high viscosity and the large difference in diameters between the plunger and the needle means that you need to push really hard to make things come out. Half the point of doing all this is to reduce the diameter of the plunger/piston.

Good point–I’m not as experienced in working with high viscosity compounds… When I first read your idea, I thought of the existing extruders and caulk-guns, but when you mentioned trying to reduce the diameter of the piston section, I thought about a straw in a milk shake. You could start with the current syringe concept, but add an inner canula that works like the ‘hole punch’ you described: you pull it back with the plunger, the flux fills the gap, then slide the inner canula back into place, like a straw going into a milk-shake, leaving the plunger primed to push the flux only through the inner canula to the luer tip. You’d have to reload it more frequently as the volume in the device diminishes, but given the goal of depositing only a tiny amount, that shouldn’t be a problem. The caulk-gun mechanism would be ideal for driving the plunger–and isn’t overly complicated… that’s going back to what you described in your post from 10/22 about a steel rod with a plunger. Add the reverse of the caulk-gun mechanism (turn the plunger to disengage the teeth so the inner canula can be pushed through the flux, refilling it and priming the plunger, then turn the plunger to re-engage the teeth on the trigger mechanism.

Looks like I’m not the first one to want to connect a block to a luer lock though:

https://www.aliexpress.us/item/2251832607426492.html?gatewayAdapt=glo2usa4itemAdapt

So I’ve been thinking about this idea quite a lot, and I’ve come up with an alternate design. Not sure if if it’s better or worse though.

The idea is to do the same thing (two moving pistons) but instead of using linear motion, it would use rotational motion.

There are lots of ways to do this, but the simplest probably looks something like this:

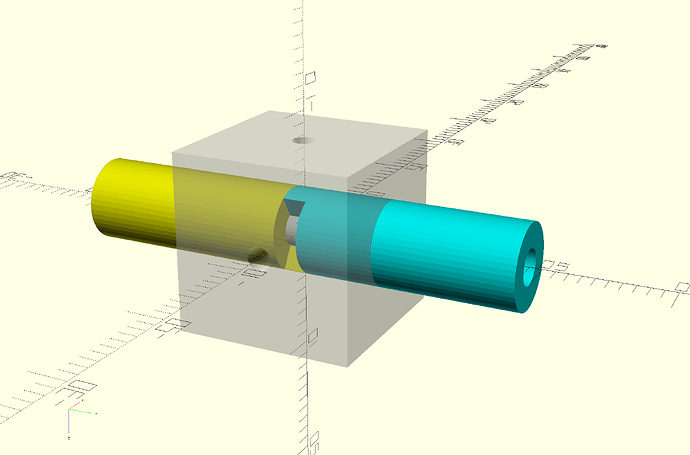

The yellow and blue parts are tubes which would be attached to servos for rotation, and there is a center pin. The semi-translucent cube has holes all the way through, the one in the front would be where the solder paste goes in, and the one in the bottom would be where it goes out.

As shown, the space between the tubes is open, so the next step would be for both tubes to rotate 90 degrees so that the opening is facing the bottom. From there, the tubes would squeeze out the solder paste until the opening between the two tubes is completely closed. At that point it rotates back 90 degrees, opens to let solder paste in, and then the cycle starts over again.

In the “pros” column, this design might be easier to implement, and take less space since it doesn’t require linear motion. I was thinking that it could be attach directly to servos, however, I’m not sure that servos are going to be great at this since there is no good way to control the speed of a servo. Rotating both tubes 90 degrees at the same time might not work well if one servo is a little faster than the other…

In the “cons” column, is the fact that these tubes have to be pushing against each other, and if that pressure isn’t strong enough, solder paste will be leaking between the yellow and blue parts.

1 Like

So, today I stumbled across something called a rapidograph, which is is very similar to the first idea in this thread. However, it’s a pen meant to work with low-viscosity ink, not something like solder paste. However, it may be possible to modify a rapidograph by adding something that pumps the needle, and if so, maybe it could work with a high viscosity fluid… maybe… I might have to buy one to try it out.

1 Like