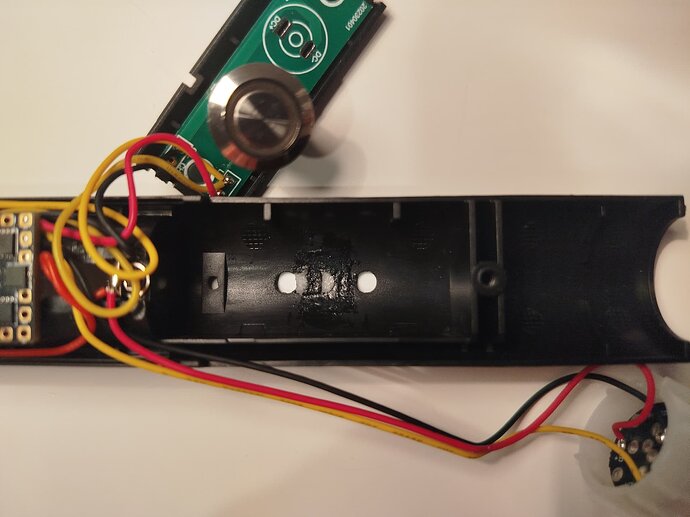

Hello! I damaged the lightsaber chassis. The hole for the retention screw has a shear failure. Please see photo attached. Could you please share with me any advice on repair? Need somehow to add material in the place where plastic was to provide bearing for the retention screw. Was thinking maybe use 3D pen?

Hey there! I waiting to see if others would chime in before I added this…

Because it’s plastic, you could consider adding a heat press brass insert. It seems a bit scary, but I think it may work well for you.

You just drill an appropriate size hole where you want the insert and press in one with a heated soldering iron. You then have a metal threaded hole where a weak plastic hole once was.

The main thing to check would be depth, but some of those I linked look thin, and also could be filed smaller before or after insertion.

3d pen is probably a good idea. I think you would want ABS for the repair, not PLA. ABS creates more fumes and particles when you melt it, but I think it would adhere better. (Unless your chassis is made of PLA.)

Thank you for the idea and link.

Thank you for sharing your thoughts. Now I know the appropriate filament for this application.

I was thinking about this the whole day… I dropped it when was practicing the force leash. The saber was attached to a leash and I was spinning it like it’s a force power. The swivel broke and saber fell on concrete floor.

Another idea I had today… Disassemble the chassis, it consists of two halfs. Attach an electronics thin tape over the hole on external face. Tape to have a cutout to create the correct hole shape. And then from internal side pour baking soda on tape and sprinkle with super glue. This should create solid material to fill the space and provide bearing for the retention screw.

Hopefully the chassis halfs are not glued together and can be disassembled. It’s from the TXQ company.

Superglue and ABS (ABS is basically superglue mixed with styrene) have a lot in common. I honestly don’t know which will be better for this particular case, but if the chassis is injection-molded or 3d-printed ABS, then both should adhere well to the plastic at least.

ABS is by far the most common plastic used for injection molding, and all legos are made out of it, so chances are good that it’s made from ABS.