Hi, while working through my increasingly complex wiring diagram and reading through the documentation, I hit a snag on this line about BLADE_ID: " IMPORTANT NOTE - BladeID requires a direct, uninterrupted connection from the board’s data pin to the main blade (usually the center pin on the hilt-side of the main blade PCB). Therefore using SubBlades with neopixel accents, crystal chamber, or NPXL LED PCBs in series with the main blade won’t work…"

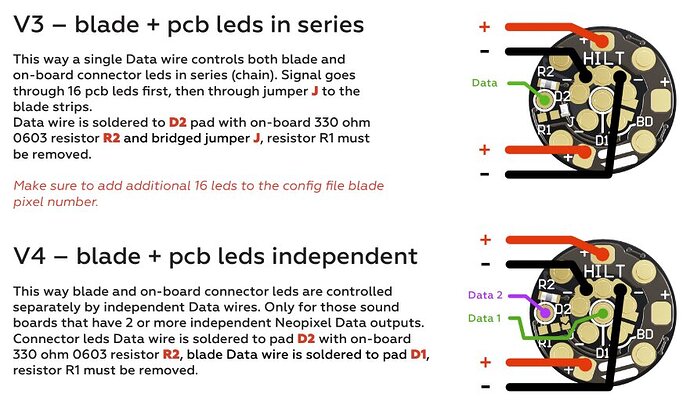

I am planning to use a Shtokworks hilt PCB, which has built-in LEDs and am choosing between the V3 and V4 wiring options from their documentation (

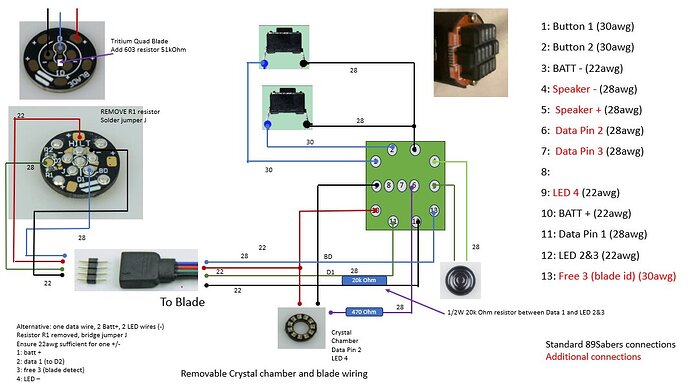

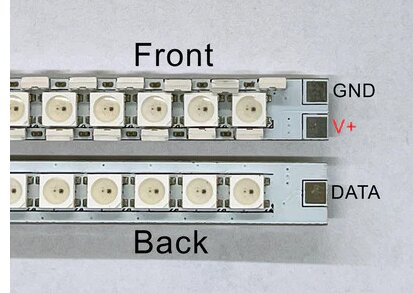

), due to a thin neck constraint on wiring, i was going to use the V3 wiring–blade + pcb leds in series, and use subblades to handle the LEDs in the PCB (even though they would not be visible when the blade was installed). On the blade side PCB, I was planning to use a 51k 0603 0.1w resistor for blade id.

I was also planning to use this chassis in other hilts–so I thought I could add a 20k ohm resistor on the hilt side for this specific hilt (1/2W), between Data 1 and LED 2+3. My understanding was that these resistors would be additive so I could trigger blade configuration specific to the blade/hilt combinations: 50k for the quad blade, 70k for the quad blade and hilt chamber, 20k for this hilt with a different blade.

None of this is wired yet–so I cannot test anything–but I thought I should ask before I start soldering… here is my draft blade config:

BladeConfig blades[] = { { 1, WS281XBladePtr<144, bladePin, Color8: - Pastebin.com

Here is my wiring diagram for this section of the hilt/blade:

To circle back to my question: can I wire the hilt pcb so the built-in LEDs are in series and still use Blade id? If not, would it work with the V4 wiring option–blade and PCB LEDs are independent (they still have shared power pins). Will a resistor on the hilt side stack? What about splitting the main blade into 4 subblades–can that be done at all with blade-id?

Oh, and one crazy question to throw in for merriment–can the same pixels be assigned to multiple blades in the bladeconfig? I was thinking it could be useful to address the blade as a whole for some styles while others would only affect a section/side of the blade.

thanks in advance–and happy holidays.