Watching Brian Conners video, and Kim Canamas results piqued my interest. Here waa my first attempt. Had to use tge force to get her to line up. While my hot air skills need work, the force is strong in me!

That’s good! You’ve taken your first step into a SMALLER world.

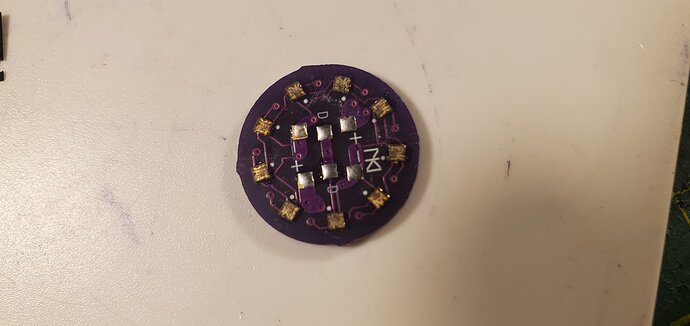

3rd attempt, much more difficult. 9 1515 smd neopixels on a custom oshpark pcb by kim canama! Thanks Brian and Kim!!!

Stencils are great. They also have a learning curve. I find that, again, less paste = less over smudging to clean up/waste, but primarily anchoring your setup properly.

I set up surrounding “walls” of 1.5mm height around the target PCB, touching and enclosing the PCB on 3 sides. Tape the surrounds down well to the bench.

When doing multiples in a batch, I place a PCB and mark position of the holes with a mechanical pencil so I can see exactly how to orient the next one the same.

Then a masking tape strip on one edge of the stencil so it hinges in and out of place. Glob, spread, lift stencil, tweezer the PCB out.

“Bob’s your Auntie” lol

I did pretty good with stencil and masking tape! Solder was neatly applied and even on pads. Hard part was orienting all the 1515s prooerly without damaging alignments on others. Hot air was quick, easy, and neat. You could see the pixels line up on the pads. I was very happy camper when it actually worked!

next up my broken usb connector,. lols I MIGHT be getting a hot air rework station, what do you suggest for me to practice on first?